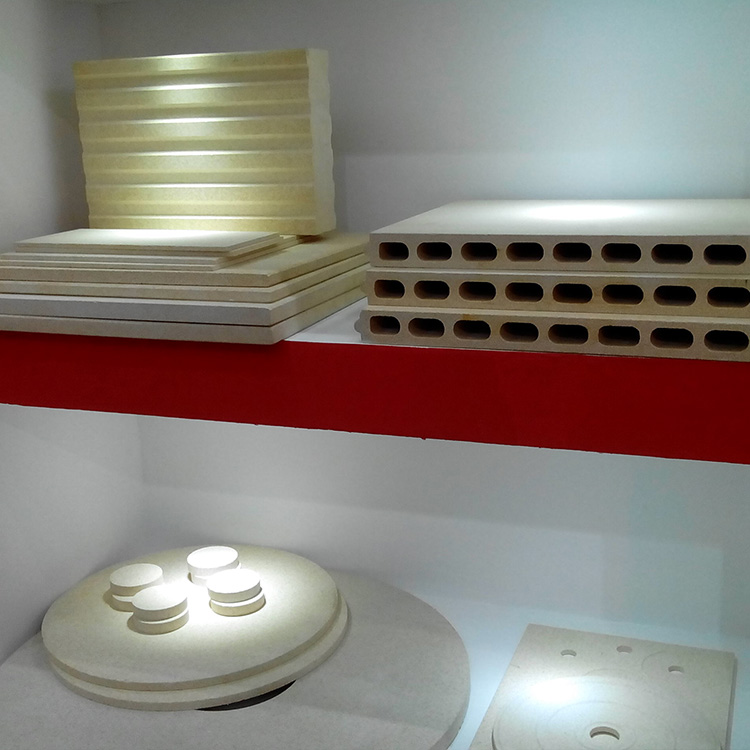

In the glass manufacturing industry, the choice of refractory materials for glass kilns is crucial. High - quality silica bricks have emerged as a top - tier solution, offering a combination of outstanding performance and practical application benefits. This article delves deep into the core performance of these silica bricks and their key applications in high - temperature kilns.

One of the most notable features of these silica bricks is their raw material. They are made from natural silica sand with an SiO₂ content exceeding 96%. This high - purity raw material endows the silica bricks with excellent high - temperature resistance. Tests have shown that these silica bricks can withstand temperatures up to 1650°C without significant deformation, ensuring stable operation in the harsh high - temperature environment of glass kilns.

Let's take a closer look at the key performance indicators of these silica bricks:

| Performance Indicator | Details |

|---|---|

| High - Temperature Resistance | Withstand up to 1650°C, maintaining structural integrity |

| High - Temperature Volume Stability | Volume change less than 0.5% at high temperatures |

| Non - Pollution to Glass Liquid | Does not introduce impurities to the glass liquid, ensuring high - quality glass products |

| Chemical Corrosion Resistance | Resistant to various chemical substances in the kiln environment |

| Low Density | Density of about 1.8 - 2.0 g/cm³, reducing the overall weight of the kiln |

In practical glass production, these silica bricks play a vital role. For example, in a large - scale glass manufacturing plant, after replacing the original refractory materials with these high - quality silica bricks, the production efficiency increased by 15%. This is mainly because the high - temperature volume stability of the silica bricks reduces the need for frequent adjustments during the production process.

Moreover, the non - pollution property of the silica bricks to the glass liquid is of great significance. It helps to produce glass products with high transparency and fewer defects, improving the overall quality of the products. In terms of cost, the silica bricks can significantly reduce the kiln maintenance cost. The chemical corrosion resistance extends the service life of the kiln, and the low - density feature reduces the energy consumption during the operation of the kiln.

The glass manufacturing industry is facing challenges such as high energy consumption, strict quality requirements, and high maintenance costs. These high - quality silica bricks offer effective solutions. Their excellent performance helps to meet the high - temperature and chemical - resistant requirements of the kiln, while also ensuring the quality of the glass products and reducing the overall cost.

In conclusion, high - quality silica bricks for glass kilns are an ideal choice for glass manufacturers. Their outstanding performance and practical application benefits can bring significant improvements to the production process. If you are looking for a reliable refractory material for your glass kiln, don't miss out on these high - quality silica bricks. Click here to learn more about our glass kiln silica bricks