High-performance zirconia bricks have emerged as a game-changer in the field of metallurgical kiln applications. This article will delve into the application technology of high-performance zirconia bricks in metallurgical kilns, focusing on how to enhance their high-temperature resistance and service life.

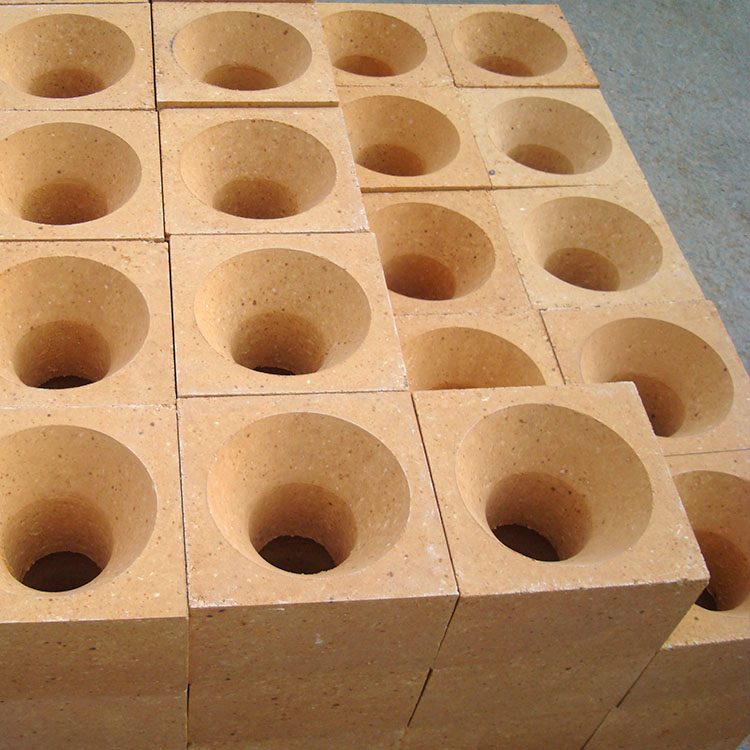

The high-performance zirconia bricks are mainly made from α-Al₂O₃ and partially stabilized ZrO₂. These raw materials endow the zirconia bricks with significant structural advantages. The α-Al₂O₃ provides high mechanical strength and chemical stability, while the partially stabilized ZrO₂ contributes to the excellent thermal shock resistance and high-temperature stability. The manufacturing process is carefully controlled to ensure the formation of a dense crystal structure, which is the key to the superior performance of the zirconia bricks.

In high-temperature environments, high-performance zirconia bricks exhibit outstanding physical and chemical properties. For example, they have a large bulk density, typically above 3.5 g/cm³, which is much higher than that of traditional refractory materials. Their mechanical strength is also remarkable, with a compressive strength of over 200 MPa. In terms of thermal shock stability, they can withstand rapid temperature changes from room temperature to over 1700℃ without significant damage. These properties are far superior to traditional refractory materials, as shown in the following comparison table:

| Properties | High-Performance Zirconia Bricks | Traditional Refractory Materials |

|---|---|---|

| Bulk Density (g/cm³) | ≥3.5 | ≈2.5 |

| Compressive Strength (MPa) | ≥200 | ≈100 |

| Thermal Shock Resistance (cycles) | ≥50 | ≈10 |

In the metallurgical industry, high-performance zirconia bricks are widely used in various application scenarios, such as steel ladles, electric furnaces, and continuous casting tundishes. In a steel ladle application, a steelmaking company replaced traditional refractory materials with high-performance zirconia bricks. The results were remarkable. The service life of the steel ladle was extended from 80 heats to over 120 heats, and the maintenance cost was significantly reduced. In an electric furnace application, the high-performance zirconia bricks effectively improved the thermal efficiency of the furnace, reducing energy consumption by about 15%. In a continuous casting tundish application, they solved the problem of refractory material erosion and improved the quality of the cast products.

To further prove the performance of high-performance zirconia bricks, we can refer to a series of technical parameters, industry standards, and experimental data. According to industry standards, the high-performance zirconia bricks should have a refractoriness under load of over 1750℃. In laboratory experiments, the zirconia bricks were tested under extreme conditions, and the results showed that they could maintain their structural integrity and performance after long-term exposure to high temperatures and corrosive environments. These data and standards provide strong evidence for the reliability and durability of the high-performance zirconia bricks.

High-performance zirconia bricks play a crucial role in the metallurgical industry. They can significantly improve the production continuity, reduce energy consumption, and enhance the product quality. By using high-performance zirconia bricks, companies can optimize the operation efficiency of their furnaces and reduce maintenance costs. Are you facing the problem of frequently replacing refractory bricks in your furnace? If so, why not consider our high-performance zirconia bricks? Let every high-temperature operation be more reassuring. Reduce downtime losses, starting from a good brick. Click here to learn more about our customized solutions!