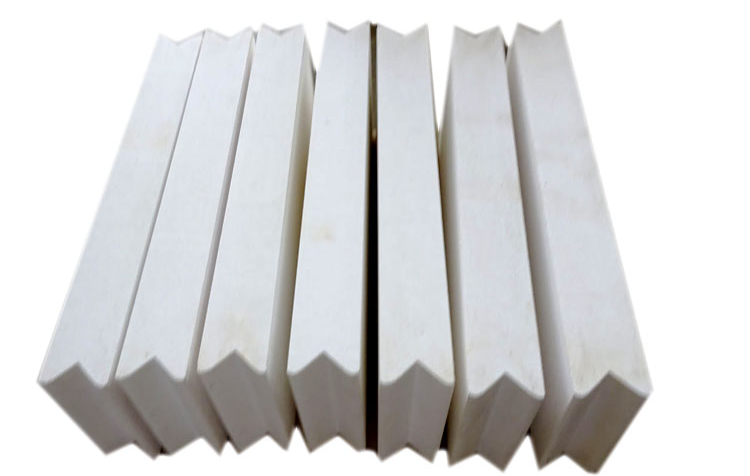

Fused silica bricks have emerged as the preferred choice for industrial kilns due to their outstanding high-temperature performance. In high-temperature industrial kiln environments, these bricks exhibit a range of physical and chemical properties that set them apart from other refractory materials.

One of the key advantages of fused silica bricks is their high viscosity. At high temperatures, a high viscosity helps the bricks maintain their shape and structure, preventing them from deforming easily. According to experimental data, fused silica bricks can maintain a stable viscosity even at temperatures up to 1600°C, which is crucial for the long - term operation of industrial kilns.

Strength is another critical factor. Fused silica bricks possess high strength, enabling them to withstand the mechanical stress and pressure in industrial kilns. Tests show that the compressive strength of fused silica bricks can reach up to 50 MPa, which is significantly higher than many common refractory materials. This high strength ensures that the bricks can endure the harsh conditions inside the kiln without cracking or breaking.

Fused silica bricks have excellent resistance to slag. In industrial kilns, slag can corrode refractory materials, reducing their service life. However, fused silica bricks form a stable layer on the surface when in contact with slag, preventing further penetration and corrosion. Studies indicate that the slag resistance of fused silica bricks is 30% better than that of some traditional refractory materials.

Moreover, they also have good resistance to impact. In the process of material loading and unloading in the kiln, the bricks may be subject to impact. The high - impact resistance of fused silica bricks ensures their integrity and durability. For example, in a test simulating the impact in a kiln, fused silica bricks showed only minor surface damage after multiple impacts.

The thermal stability of fused silica bricks is one of their most remarkable features. They have a low thermal conductivity, which means less heat is transferred through the bricks. The thermal conductivity of fused silica bricks is about 1.0 W/(m·K) at high temperatures, compared to 1.5 - 2.0 W/(m·K) for some common refractory materials. This low thermal conductivity helps to reduce heat loss in industrial kilns, improving energy efficiency.

Additionally, fused silica bricks have very small drying and firing shrinkage rates. The drying shrinkage rate is less than 0.5%, and the firing shrinkage rate is less than 1%. These small shrinkage rates ensure that the bricks maintain their dimensional stability during the production and use processes, reducing the risk of cracking due to shrinkage.

.jpg)

When comparing fused silica bricks with other common refractory materials such as clay bricks and alumina bricks, significant differences can be observed in terms of thermal expansion and heat conduction. The thermal expansion coefficient of fused silica bricks is relatively low, about 0.5×10⁻⁶/°C, while clay bricks may have a thermal expansion coefficient of 5 - 8×10⁻⁶/°C. This low thermal expansion coefficient means that fused silica bricks are less likely to crack due to thermal stress.

Sunrise Factory is committed to producing high - quality fused silica bricks. The factory uses advanced production processes, including precision melting and molding techniques, to ensure the consistency and quality of each brick. A strict quality control system is in place at every stage of production, from raw material inspection to finished product testing. This rigorous quality management ensures that the products meet the highest standards and provide reliable performance in industrial kilns.

In a glass - making industrial kiln, the use of fused silica bricks has significantly improved the service life of the kiln. Previously, the kiln needed to be repaired every 6 months using traditional refractory materials. After replacing with fused silica bricks, the repair interval has been extended to 18 months, reducing maintenance costs and improving production efficiency.

Are you interested in learning more about how fused silica bricks can benefit your industrial kilns? Feel free to leave a message below or click here to consult for more detailed information. Let's explore how our high - quality fused silica bricks can help your business achieve more efficient and stable high - temperature operations.