.jpg?x-oss-process=image/resize,h_1000,m_lfit/format,webp)

High-temperature environments pose significant challenges for industrial applications, especially in sectors such as steelmaking, cement production, and glass manufacturing. The selection of high-performance refractory materials is crucial to ensure operational efficiency, safety, and longevity of equipment. Among these, high-temperature magnesia-chrome bricks have gained widespread recognition for their superior performance under extreme conditions.

.jpg)

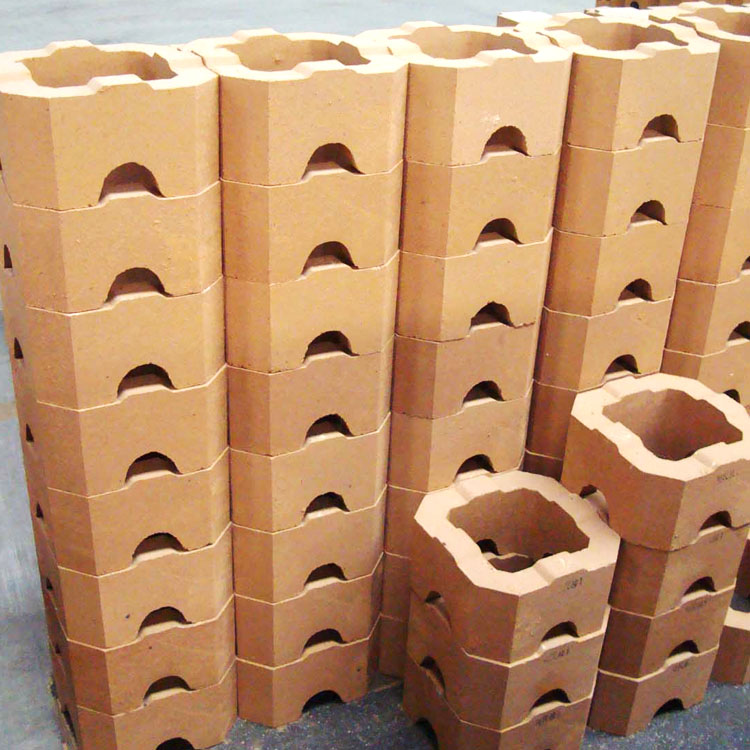

The exceptional performance of high-temperature magnesia-chrome bricks stems from the special raw materials used in their production. These bricks are primarily composed of magnesium oxide (MgO) and chromium oxide (Cr₂O₃), which provide excellent thermal stability and resistance to chemical erosion.

Compared to traditional magnesia bricks, which consist mainly of MgO, magnesia-chrome bricks offer enhanced structural integrity and a higher melting point. This makes them particularly suitable for applications where temperatures exceed 1600°C.

High-temperature magnesia-chrome bricks are known for their outstanding properties, including:

To better understand the advantages of high-temperature magnesia-chrome bricks, let’s compare them with conventional magnesia bricks using real-world data.

| Property | Magnesia-Chrome Bricks | Magnesia Bricks |

|---|---|---|

| Refractoriness | ≥ 1750°C | ≈ 1600°C |

| Thermal Conductivity | 0.8–1.2 W/m·K | 1.0–1.5 W/m·K |

| Porosity | ≤ 15% | 18–25% |

| Resistance to Slag Erosion | Excellent | Moderate |

| Service Life | Up to 3 years | 1–2 years |

Many industrial clients have reported significant improvements after switching to high-temperature magnesia-chrome bricks. For example, a leading steel plant in Southeast Asia replaced its old magnesia bricks with our high-temperature magnesia-chrome bricks in its blast furnace lining. After one year of operation, the furnace showed no signs of wear, while the previous lining had already required partial replacement.

Another case study from a glass manufacturing facility in Europe demonstrated that the use of high-temperature magnesia-chrome bricks reduced energy consumption by up to 8% due to better heat retention and lower thermal losses.

Our high-temperature magnesia-chrome bricks are manufactured using advanced techniques and high-purity raw materials, ensuring consistent quality and reliable performance. With a proven track record in multiple industries, we provide solutions tailored to your specific needs.

Whether you are looking to improve furnace efficiency, reduce maintenance costs, or extend the service life of your refractory linings, our products are designed to meet and exceed your expectations.