Are you struggling with frequent failures in your high-temperature industrial equipment? The magnesium-aluminum spinel brick has emerged as a game-changer in refractory materials, offering superior thermal shock resistance, volume stability, and corrosion resistance. These qualities significantly minimize equipment downtime while extending operational lifespan—ultimately leading to reduced maintenance costs and enhanced production efficiency.

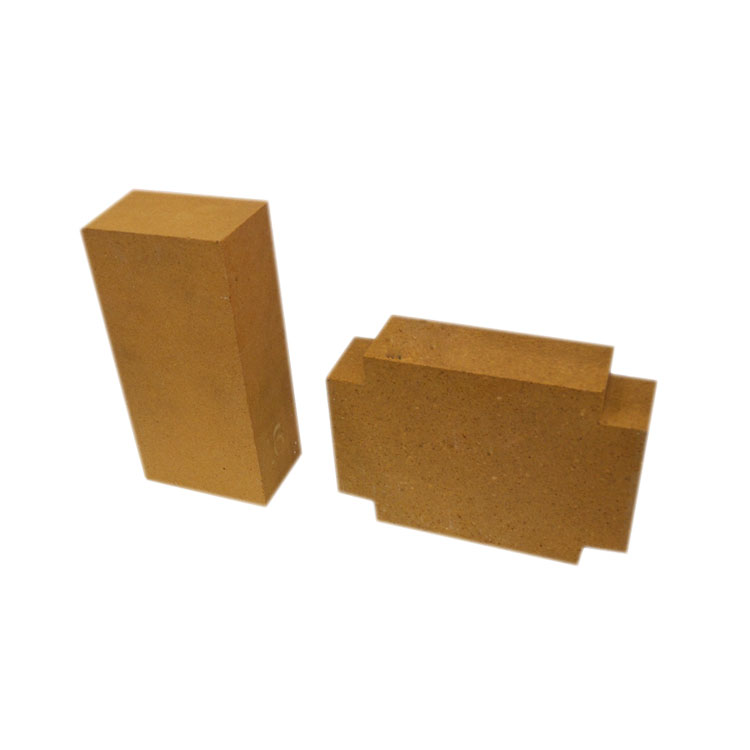

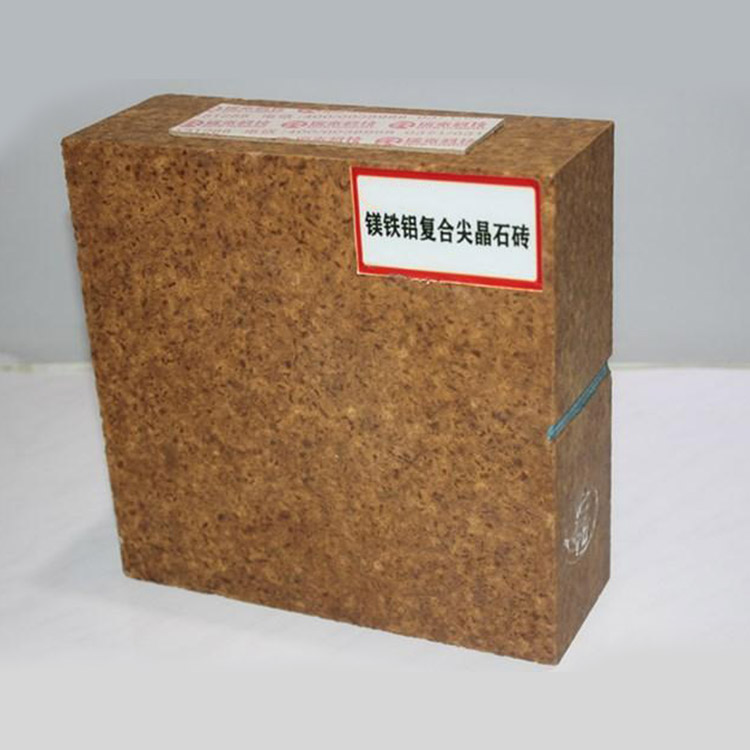

Magnesium-aluminum spinel bricks are advanced refractory linings specifically designed for harsh high-temperature environments such as steelmaking furnaces, cement kilns, and glass melting units. Unlike conventional firebricks, these bricks exhibit a unique crystalline structure that imparts excellent thermal shock stability and corrosion resistance against slag and molten metal infiltration.

Their key technical advantages include:

| Performance Metric | Traditional Firebricks | Magnesium-Aluminum Spinel Bricks |

|---|---|---|

| Thermal Shock Resistance | Moderate (Cracks form after ~50 cycles) | Excellent (Stable beyond 200 cycles) |

| Volume Stability | Lower (Up to 3% shrinkage at 1500°C) | High (Less than 1% change at 1500°C) |

| Corrosion Resistance | Moderate (Affected by slag infiltration) | Superior (Minimal slag impact) |

Case Summary: Steel Industry Furnace Retrofit

A leading steel manufacturer replaced traditional refractory lining with magnesium-aluminum spinel bricks in their electric arc furnace. Within six months, equipment downtime reduced by 30%, and lining life extended from 9 to 15 months, equating to a 66% increase. Maintenance costs dropped nearly 25%, directly contributing to operational savings and increased throughput.

Similarly, in the cement manufacturing sector, retrofit projects employing spinel bricks have reported improved kiln stability under high thermal loads, with a 40% decrease in unscheduled shutdowns due to lining failures.

Glass factories utilizing these advanced refractory bricks observe lower contamination in molten glass batches, enhancing product quality and reducing scrap rates by up to 15%.

According to aggregated customer data, companies using magnesium-aluminum spinel bricks have experienced:

What is your current refractory failure rate, and how much downtime does it cause your operations monthly? Could upgrading to magnesium-aluminum spinel bricks create a measurable difference in your equipment's reliability?

Industrial operations are increasingly focused on cost-efficiency and maximizing equipment uptime. Incorporating high-performance refractory materials like magnesium-aluminum spinel bricks aligns perfectly with these strategic goals.

For companies navigating the challenges of energy-intensive processes and harsh high-temperature conditions, investing in smarter refractory solutions translates into tangible returns on investment.

Request Your Free Sample Trial Today