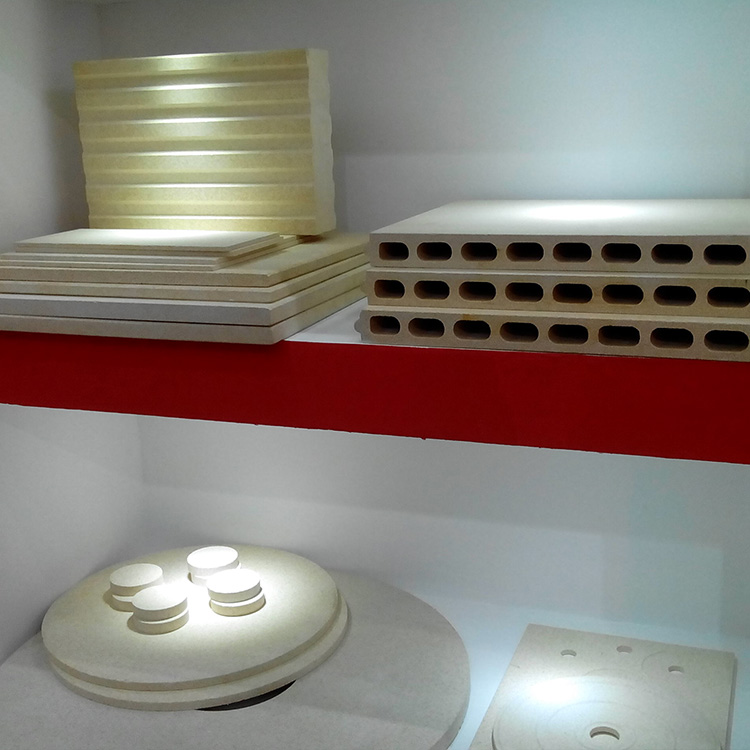

In the glass manufacturing industry, the choice of refractory materials is crucial for ensuring the quality of glass products, improving production efficiency, and reducing costs. High - quality silica bricks are one of the most popular refractory materials used in glass furnaces. This article will delve into the core performance advantages, practical application values of high - quality silica bricks for glass furnaces, and analyze the concerns of customers in the export market.

High - quality silica bricks are made from natural raw materials with a high SiO₂ content, usually over 95%. This high SiO₂ content endows silica bricks with excellent high - temperature resistance. In a laboratory experiment, silica bricks with a SiO₂ content of 96% could withstand a temperature of up to 1700°C without significant deformation, while ordinary refractory bricks could only bear around 1500°C.

Another significant advantage is their high - temperature volume stability. During the operation of a glass furnace, the temperature often fluctuates. High - quality silica bricks can maintain a stable volume under such conditions. For example, in a glass factory in Germany, after continuous operation at high temperatures for 3 months, the volume change rate of high - quality silica bricks was less than 0.5%, ensuring the structural integrity of the furnace.

Silica bricks also have good chemical corrosion resistance. They can resist the corrosion of various chemical substances in the glass melting process, such as alkalis and acids. In a long - term corrosion experiment, after being exposed to a corrosive environment for 6 months, the weight loss of high - quality silica bricks was only 3%, much lower than that of other refractory materials.

Moreover, high - quality silica bricks do not contaminate the glass liquid. Their pure composition ensures that no impurities are introduced into the glass during the melting process, which is essential for producing high - quality glass products.

In the actual glass production process, high - quality silica bricks play a vital role in improving product quality. By maintaining a stable high - temperature environment and preventing contamination of the glass liquid, they help to produce glass products with uniform quality, fewer bubbles, and better optical properties.

They also contribute to improving production efficiency. Their high - temperature stability allows for continuous high - temperature operation of the glass furnace, reducing the frequency of furnace shutdowns for maintenance. For example, a glass factory in the United States increased its production efficiency by 15% after replacing ordinary refractory bricks with high - quality silica bricks.

In terms of cost reduction, high - quality silica bricks can effectively reduce the maintenance cost of the glass furnace. Their long service life and good corrosion resistance mean that the frequency of brick replacement is significantly reduced. A glass factory in Italy reported a 20% reduction in furnace maintenance costs after using high - quality silica bricks.

When it comes to the export market, customers are mainly concerned about product performance, price - performance ratio, and after - sales service. They need to ensure that the silica bricks can meet the specific requirements of their glass furnaces. Our high - quality silica bricks, with their excellent performance and reasonable price, can fully meet the needs of different customers.

We also provide comprehensive after - sales service, including installation guidance, technical support, and regular follow - up. This ensures that customers can use our products with confidence and achieve the best results in their glass production.

Are you looking for high - quality silica bricks to improve your glass production? Click here to explore our products and get in touch with us!