In the production of alkali-free glass fiber furnaces, the industry is grappling with significant challenges. The current alkali-free glass fiber furnaces are plagued by issues such as poor stability, rapid wear - and - tear, and frequent maintenance requirements. These problems not only disrupt the production process but also lead to high costs for enterprises. For instance, on average, a typical alkali - free glass fiber furnace needs to be shut down for maintenance about 5 - 8 times a year, with each shutdown resulting in an average loss of $10,000 - $20,000 in production time and replacement costs. This situation has become a major headache for manufacturers in the industry.

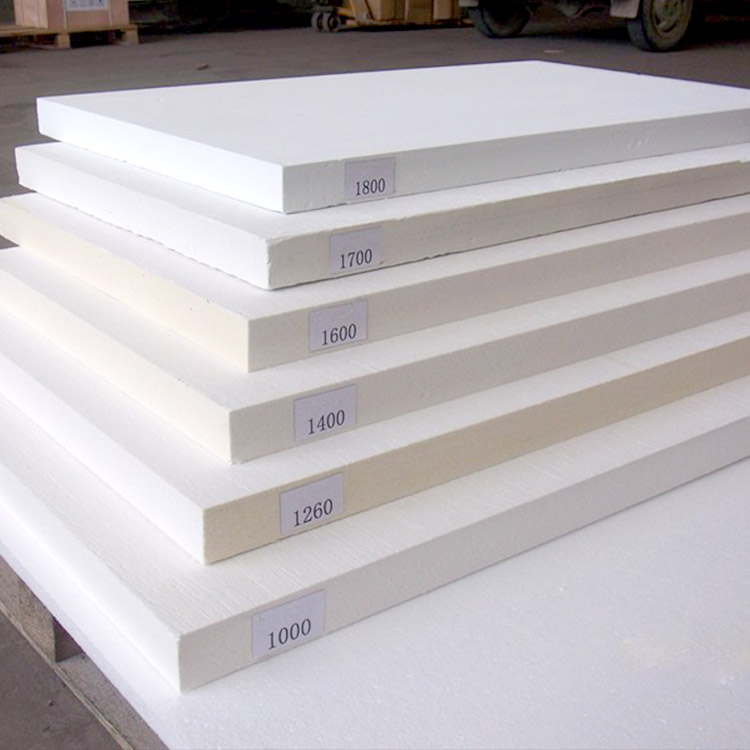

Enter the dense zirconium block, a revolutionary solution to these long - standing problems. Let's delve into its core advantages. First, its crystal structure is extremely dense. Compared with ordinary refractory materials, the density of the dense zirconium block is 20% - 30% higher. This high density gives it excellent physical properties. In terms of volume density, it can reach up to 4.5 - 5.0 g/cm³, which is significantly higher than the 3.0 - 3.5 g/cm³ of common materials used in furnaces. This large volume density means that it can withstand greater pressure and stress.

When it comes to high - temperature strength, the dense zirconium block truly shines. It can maintain its structural integrity at temperatures up to 1600 - 1700°C, while ordinary materials may start to deform or lose their strength at around 1300 - 1400°C. Its high - temperature strength is about 1.5 - 2 times that of common refractory materials. Moreover, it has outstanding wear resistance. In a wear - resistance test, the wear rate of the dense zirconium block is only 10% - 15% of that of ordinary materials, which is a remarkable difference. Chemically, it is highly stable and can resist the corrosion of various chemical substances in the glass - making process.

| Properties | Dense Zirconium Block | Ordinary Material |

|---|---|---|

| Volume Density (g/cm³) | 4.5 - 5.0 | 3.0 - 3.5 |

| High - temperature Strength (MPa) | 150 - 200 | 80 - 120 |

| Wear Rate | 10% - 15% of ordinary materials | N/A |

Now, let's look at its application scenarios. In high - stress areas such as the pool inserts and casing blocks of the furnace, the dense zirconium block shows outstanding performance. In the pool inserts, where the glass melt is in direct contact with the material, the dense zirconium block can effectively resist the thermal shock caused by the sudden change of temperature. The thermal shock resistance of the dense zirconium block is 2 - 3 times that of ordinary materials, which means it can better withstand the repeated heating and cooling cycles without cracking or breaking. In the casing blocks, it can solve the problems of creep and corrosion. Creep is a major issue in high - temperature environments, but the dense zirconium block has a very low creep rate, ensuring the long - term stability of the furnace structure.

The real - world results of using the dense zirconium block are truly impressive. According to actual test data, using this product can increase the furnace life by up to 30%. For example, if the original service life of a furnace is 3 years, after using the dense zirconium block, it can be extended to about 3.9 years. This significant increase in furnace life means a substantial reduction in the frequency of shutdowns and replacements. Enterprises can save up to 20% - 30% in annual maintenance costs. A certain glass fiber manufacturing enterprise reported that after using the dense zirconium block, their annual maintenance cost decreased from $200,000 to $140,000 - $160,000, and the production continuity was greatly improved.

In conclusion, the dense zirconium block is a game - changer for the alkali - free glass fiber furnace industry. It offers a scientific solution to upgrade your furnace, making it more durable and more worry - free. If you are looking to enhance the efficiency and stability of your furnace, don't miss this opportunity. Click here to learn more about how the dense zirconium block can transform your production process and take your business to the next level.