Common High-Temperature Kiln Failures and Practical Solutions Using Magnesia Bricks

This article delves into the frequent operational challenges faced by high-temperature kilns, emphasizing the superior properties of magnesia bricks and their practical application in enhancing kiln stability and production efficiency. Supported by scientific data and real-world case studies, it highlights how magnesia bricks effectively address issues such as alkali slag corrosion and poor thermal stability. The guide offers actionable solutions to help industries improve operational reliability and strengthen market competitiveness.

Addressing Common High-Temperature Kiln Failures with Magnesia Bricks: A Practical Guide

Insight: High-temperature kiln operations face persistent challenges due to corrosive alkaline slag infiltration and thermal instability. Magnesia bricks offer superior resistance and durability, ensuring operational stability and improved production efficiency.

Understanding High-Temperature Kiln Challenges

Industrial high-temperature kilns, such as those used in glass production, cement, and metallurgical processes, are subject to severe operational stresses. Typical failures include refractory lining degradation from alkaline slag corrosion, thermal spalling due to cyclical heating and cooling, and mechanical wear caused by thermal shock. According to recent industry surveys, refractory-related downtimes can account for up to 20% of total kiln maintenance hours, directly impacting production throughput and cost efficiency.

Why Magnesia Bricks Excel in Kiln Maintenance

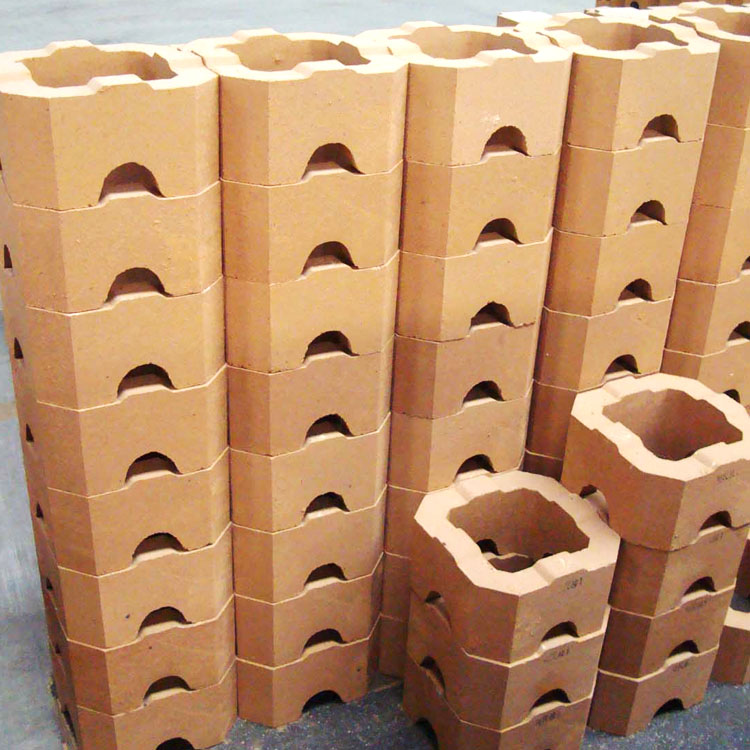

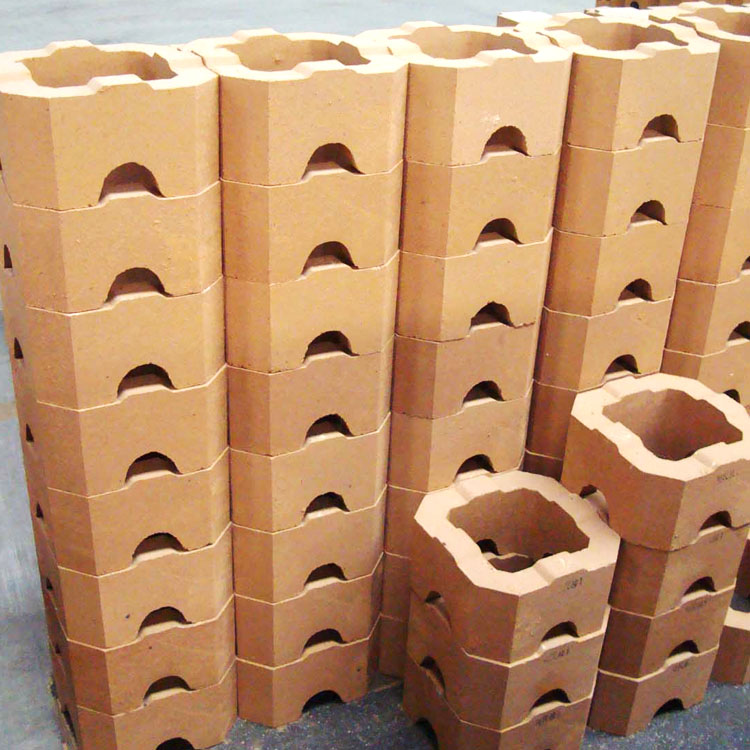

Magnesia bricks distinguish themselves through exceptional physical and chemical properties:

- High Alkali Slag Resistance: Magnesia (MgO) effectively neutralizes alkaline components in slags, dramatically reducing corrosion rates compared to traditional alumina bricks.

- Superior Thermal Stability: With melting points above 2800°C and low thermal conductivity, magnesia bricks maintain integrity in rapid temperature fluctuations and prolonged high-heat exposure.

- Mechanical Strength: Optimized bonding phases and dense microstructure provide enhanced resistance to spalling and cracking during thermal shock cycles.

Case Study: Magnesia Bricks in Glass Furnace Sidewall and Regenerator

A leading glass manufacturer recently replaced conventional alumina bricks in the regenerator and sidewall of their high-temperature glass furnace with high-quality magnesia bricks. Over 18 months, the plant recorded a remarkable 35% reduction in refractory maintenance downtime. Corrosion rates by alkaline slags dropped by 40%, directly contributing to uninterrupted production cycles and energy savings due to improved heat retention.

| Parameter |

Alumina Bricks |

Magnesia Bricks |

| Alkali Slag Corrosion Rate |

100% |

60% |

| Thermal Shock Resistance Cycles |

60 cycles |

>120 cycles |

| Service Life in Kiln |

12-15 months |

20-24 months |

| Energy Efficiency Improvement |

Baseline |

+7.5% |

Customer Feedback and Industry Trends

Feedback from multiple international clients highlights magnesia bricks not only extend the refractory lining's lifespan but also decrease unscheduled shutdowns — a critical factor for businesses in competitive markets. Industry trends indicate a growing preference for refractory materials with multi-functional performance, where magnesia bricks meet rising demands for environmental compliance, fuel efficiency, and reduced carbon footprint.

How Adopting Magnesia Bricks Enhances Your Competitive Edge

Selecting magnesia bricks as the cornerstone of kiln maintenance strategy translates into measurable benefits:

- Operational Continuity: Fewer repairs and longer service intervals minimize production disruptions.

- Cost Optimization: Reduced refractory consumption and enhanced energy efficiency cut overall expenditures.

- Sustainability: Improved resource utilization aligns with global pressures toward greener industrial processes.