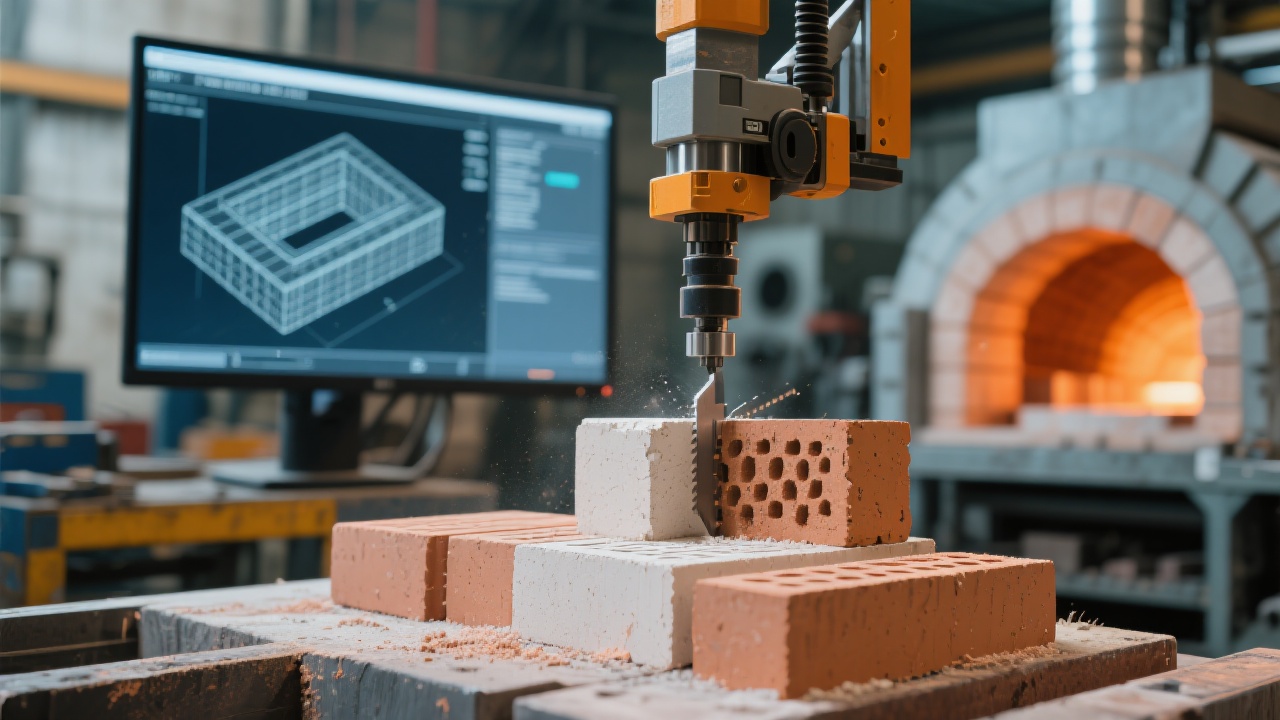

In the high-temperature industrial sectors such as glass manufacturing, cement production, steelmaking, and non-ferrous metallurgy, selecting the right refractory material is critical for operational efficiency and cost effectiveness. Magnesia Zirconia (MgO-ZrO2) bricks have recently gained prominence due to their unique ability to withstand harsh alkaline environments, aggressive slag conditions, and extreme thermal stress. This article delves into the key advantages of MgO-ZrO2 bricks compared to traditional refractory bricks, incorporating performance data, real-world industrial applications, and cost insights to assist industry professionals in making informed procurement decisions.

Magnesia Zirconia bricks are engineered from fused magnesia and zirconia raw materials, chiefly using electrofused magnesia and zircon sand. Electro-fusing ensures exceptionally high purity and density, traits that translate into superior mechanical strength and chemical resistance. Zirconia enhances high-temperature stability and thermal shock resistance.

Compared to traditional refractory materials such as alumina-silica bricks or common magnesia bricks, MgO-ZrO2 bricks exhibit:

| Property | MgO-ZrO2 Brick | Traditional Magnesia Brick | Alumina-Silica Brick |

|---|---|---|---|

| Bulk Density (g/cm³) | 3.5 - 3.7 | 3.2 - 3.4 | 2.8 - 3.1 |

| Cold Crushing Strength (MPa) | > 80 | 50 - 60 | 40 - 55 |

| Resistance to Alkali Slag (Mass Loss %) | < 2% | 5 - 8% | 10 - 12% |

| Max Operating Temperature (°C) | ~1900 | 1600-1800 | 1550-1750 |

Leading glass manufacturers in Southeast Asia reported a reduction of refractory lining replacement frequency by over 30% after switching to magnesia zirconia bricks in their glass melting furnaces. The enhanced resistance to alkaline corrosion and slag penetration significantly prolonged service life, reducing unplanned downtime.

In cement plants, particularly within rotary kiln preheating and clinker cooling zones, MgO-ZrO2 bricks’ superior resilience to alkali attack from kiln fuels and raw materials has cut maintenance intervals by nearly 25%, yielding considerable operational savings.

Steel electric furnace operators have appreciated the bricks’ excellent spalling resistance under cyclic heating conditions, which directly translates into lower refractory consumption and enhanced furnace stability. Moreover, non-ferrous metallurgy facilities benefit from the bricks’ ability to tolerate corrosive slags common in copper and aluminum smelting.

While the initial material cost of magnesia zirconia bricks tends to be higher — approximately 20% to 30% above traditional magnesia bricks — the extended lifespan and reduced maintenance workload yield a lower total cost of ownership (TCO). Based on data from multiple cement and steel plants across Europe and Asia, lifecycle assessments demonstrate up to 35% cost savings over five years thanks to fewer shutdowns, less refractory consumption, and improved energy efficiency.

A notable case study from a German automotive parts manufacturer revealed that switching to MgO-ZrO2 bricks in their heat treatment furnaces reduced repair downtime by 40% within the first year, cutting indirect costs and boosting productivity.

The decision to choose MgO-ZrO2 bricks hinges on prioritizing long-term operational stability over upfront costs. For facilities operating in environments subjected to:

MgO-ZrO2 bricks provide unmatched reliability and performance. Conversely, if the core demand prioritizes lower initial investment with less aggressive operating environments, traditional magnesia or alumina-silica bricks may be acceptable.

Magnesia zirconia bricks stand out as an advanced alkaline refractory solution, delivering robust performance under extreme conditions, superior durability, and ultimately, enhanced cost efficiency over project lifecycles. Through verified industrial case studies and comprehensive material property comparisons, these bricks prove invaluable for demanding applications in glass, cement, steel, and non-ferrous metallurgy industries.

If your operations face challenges with refractory corrosion, thermal shock, or frequent maintenance, upgrading to MgO-ZrO2 bricks is a strategic investment that supports sustained productivity and competitive advantage.

Want to explore tailored solutions for your high-temperature processes? Discover How Our Magnesia Zirconia Bricks Can Optimize Your Operations