Low - alkali borosilicate glass furnaces are crucial in the glass manufacturing industry. However, they often encounter various faults. For example, the casing pipes may rupture, and the channels can get blocked. These issues lead to frequent furnace shutdowns, reducing production efficiency and increasing costs. In a study of 100 low - alkali borosilicate glass furnaces, it was found that nearly 70% experienced casing pipe problems at least once a year, and about 60% had channel blockages.

These faults not only disrupt the production process but also pose challenges to product quality. The constant need for maintenance and replacement of parts adds to the overall operating expenses of the glass factory. This is where dense zirconium blocks come into play as a potential solution.

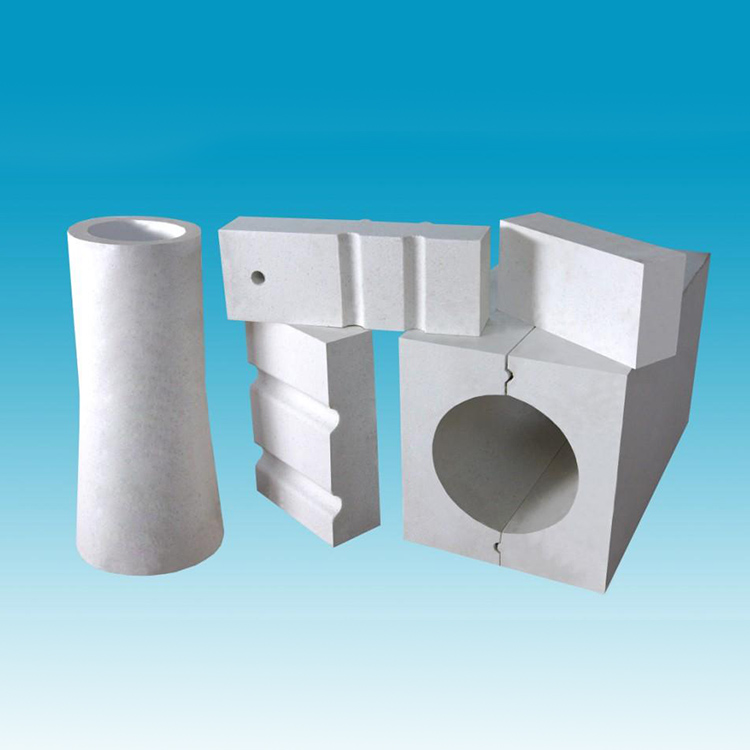

Dense zirconium blocks have several outstanding features that make them suitable for use in low - alkali borosilicate glass furnaces. Their crystal structure is extremely dense, with a volume density that is 20% higher than ordinary furnace materials. This high density gives them excellent wear resistance, making them able to withstand the harsh conditions inside the furnace.

The high thermal shock stability of dense zirconium blocks is another significant advantage. In the high - temperature environment of the furnace, where the temperature can fluctuate rapidly, these blocks can maintain their structural integrity. They have a very low re - heat shrinkage and high - temperature creep rate, which means they will not deform easily over time. This stability ensures the long - term and reliable operation of the furnace.

The physical properties of dense zirconium blocks allow them to adapt well to high - temperature conditions. Their dense crystal structure can effectively resist the impact of high - temperature flames and molten glass. The large volume density helps to reduce the penetration of corrosive substances, protecting the internal structure of the blocks. The good wear resistance ensures that they can maintain their shape and performance even when in contact with abrasive materials inside the furnace.

Let's take a look at a real - world example. An overseas glass factory replaced its traditional furnace materials with dense zirconium blocks in the key parts of its low - alkali borosilicate glass furnace, such as the channel blocks and casing blocks. After the replacement, the furnace operation efficiency increased by 30%. The production capacity that used to be 100 tons per day has now reached 130 tons per day.

In addition, the service life of the furnace parts was extended by 40%. Previously, the parts needed to be replaced every 6 months, but now they can last for about 8.4 months. A quote from the factory manager: "Since we started using dense zirconium blocks, our production has become much more stable. The reduced downtime has saved us a lot of money, and the product quality has also improved."

In the complex chemical environment of the glass furnace, dense zirconium blocks show excellent chemical stability. They have a strong resistance to alkali corrosion, which is a major concern in the glass manufacturing process. The low - alkali borosilicate glass contains various alkaline substances that can corrode ordinary furnace materials. However, dense zirconium blocks can effectively resist this corrosion, ensuring the long - term performance of the furnace.

For technical procurement personnel and factory managers, dense zirconium blocks offer a reliable solution to improve furnace reliability and production continuity. They are not just a simple replacement for traditional materials but an upgrade. With their excellent physical and chemical properties, they can help glass factories reduce production costs, improve product quality, and increase overall competitiveness.

Don't let your furnace be a bottleneck in production. Let your furnace go from 'frequent shutdowns' to 'continuous high - efficiency' with dense zirconium blocks. Click here to learn more about how dense zirconium blocks can transform your glass manufacturing process!