In the field of non-alkali glass fiber kilns, stability issues and high maintenance costs have long been pressing concerns. Traditional refractory materials often struggle to meet the demanding requirements of high-temperature and high-stress operating conditions, leading to frequent breakdowns and costly maintenance.

Dense zirconium blocks stand out as a revolutionary solution. Their outstanding performance is rooted in their unique physical properties. With a dense crystal structure and high bulk density, these blocks possess a scientific edge. The dense crystal structure ensures fewer voids, enhancing the material's overall strength and stability.

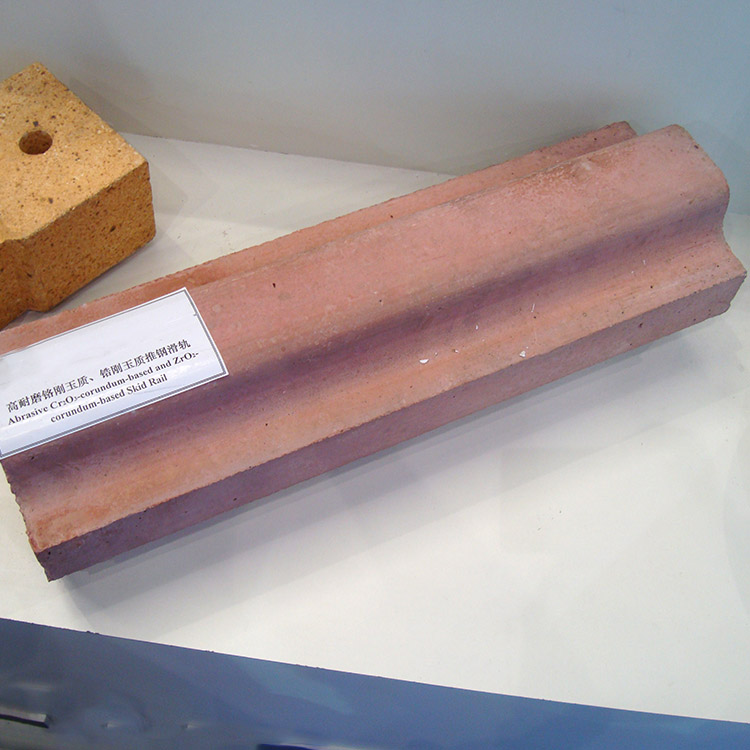

When compared with traditional refractory materials, dense zirconium blocks shine in terms of high-temperature strength, wear resistance, and chemical stability. Traditional materials may experience significant deformation or corrosion under high temperatures, while dense zirconium blocks maintain their integrity. Their high-temperature strength allows them to withstand extreme heat without losing shape, and their excellent wear resistance ensures long - term use in high - friction environments. Chemically, they are highly stable, resistant to various corrosive substances in the kiln environment.

| Material | High - Temperature Strength | Wear Resistance | Chemical Stability |

|---|---|---|---|

| Traditional Materials | Low | Poor | Vulnerable |

| Dense Zirconium Blocks | High | Excellent | Highly Stable |

In critical areas such as the molten pool inlay stones and casing blocks of non - alkali glass fiber kilns, dense zirconium blocks demonstrate their superior performance. In the molten pool inlay stones, where high - temperature and high - stress conditions prevail, the blocks' high - temperature resistance and wear resistance prevent rapid wear and damage, ensuring the stable operation of the molten pool. In casing blocks, their excellent thermal shock stability allows them to withstand sudden temperature changes without cracking, maintaining the integrity of the kiln structure.

Real - world customer data provides solid evidence of the effectiveness of dense zirconium blocks. According to customer measurements, the use of dense zirconium blocks has extended the kiln's service life by more than 30%. This significant increase in service life means fewer replacements and lower long - term costs. Additionally, the downtime of the kiln has been reduced by a substantial amount, and the maintenance frequency has decreased by 40%. This reduction in maintenance not only saves on labor and material costs but also enhances the overall production continuity.

Key Metrics:

The use of dense zirconium blocks brings comprehensive benefits to the non - alkali glass fiber kiln industry. It effectively solves the pain points of high maintenance costs and poor stability. By reducing maintenance costs and improving production efficiency, it significantly enhances the overall profitability of enterprises. Moreover, the improved stability of the kiln operation helps to improve product quality, ensuring the consistent production of high - quality non - alkali glass fiber products.

In conclusion, dense zirconium blocks are the ideal choice for the industry's upgrade. They offer a reliable solution for kiln operators looking to reduce costs, improve efficiency, and enhance product quality. If you are interested in learning more about the technical details of dense zirconium blocks or want to explore how it can transform your kiln operations, click here to get more technical information and connect with our sales team.