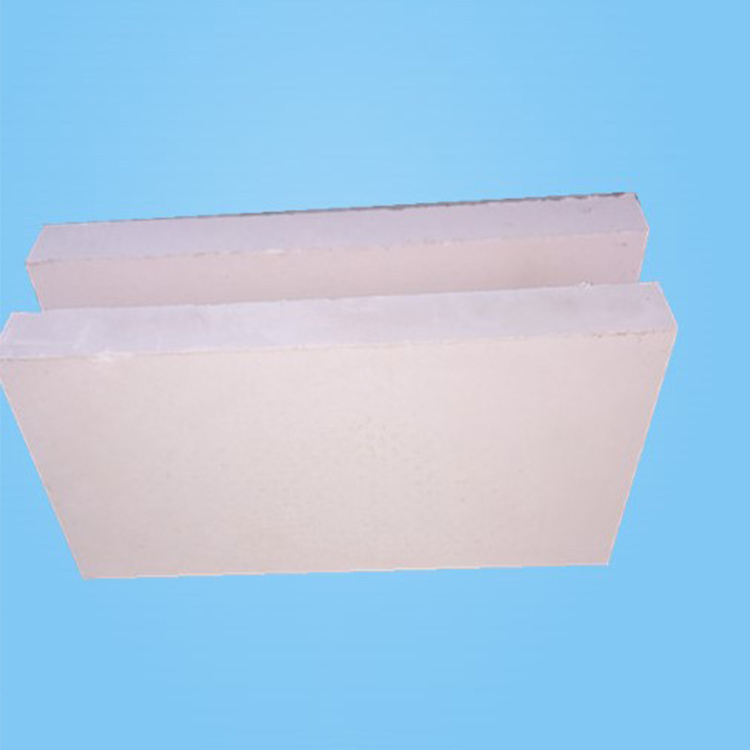

High-Quality Silica Bricks for Glass Furnaces: Enhancing Glass Forming Quality and Reducing Defect Rates

2025-11-18

Product description

This article explores how premium silica bricks made from high-purity SiO2 raw materials (>96%) deliver exceptional high-temperature resistance and dimensional stability for glass furnaces. These properties effectively minimize furnace deformation, eliminate glass melt contamination, improve glass forming quality, and significantly reduce defect rates. Through detailed analysis and real-world case studies, the core benefits of using quality silica bricks in glass production are highlighted, enabling manufacturers to achieve cost-efficient operations and extended furnace service life.

Premium Silica Bricks for Glass Furnaces: Enhancing Glass Formation Quality and Reducing Defect Rates

The glass manufacturing industry faces continual challenges in maintaining furnace integrity and ensuring the highest product quality. Central to overcoming these challenges is the choice of furnace refractory materials. Premium silica bricks, formulated with high-purity SiO2 content exceeding 96%, exhibit exceptional thermal stability and chemical resistance. These attributes play a pivotal role in minimizing furnace deformation, eliminating glass melt contamination, and ultimately boosting glass forming quality while significantly reducing defect rates.

Addressing Challenges in Glass Furnace Operations

Glass furnaces are subjected to extreme thermal cycles, chemical corrosion from molten glass, and mechanical stress. Common industry issues include refractory wear, dimensional instability, and contamination of glass melt by refractory elements. Such problems increase maintenance costs and lead to higher scrap rates, directly impacting operational efficiency and profitability.

Therefore, implementing high-grade silica bricks with enhanced material properties is essential for reducing downtime, extending furnace lifespan, and ensuring consistent glass product quality.

Material Excellence: High Purity and Superior Physical-Chemical Features

The core advantage of these silica bricks lies in their raw material quality. With SiO2 purity consistently above 96%, impurities which often compromise the brick’s structural integrity and chemical inertness are markedly reduced. This high purity ensures:

- Outstanding High-Temperature Resistance: The bricks sustain structural stability and resist deformation under temperatures exceeding 1600°C, critical for high-efficiency glass melting.

- Low Bulk Density: Offering easier installation and higher thermal insulation, these bricks reduce furnace energy consumption by up to 8% compared to conventional refractories.

- Exceptional Chemical Resistance: Resistance to molten glass corrosion prevents glass melt contamination, preserving product purity and reducing defects.

- Dimensional Stability: Maintains consistent volume with minimal expansion or contraction, reducing the incidence of mechanical fractures and furnace repair frequency.

Real-world Applications and Performance Validation

Independent testing in industrial glass furnaces validates the performance claims of these premium silica bricks:

| Performance Metric |

Premium Silica Brick |

Standard Silica Brick |

| Thermal Shrinkage at 1600°C |

< 0.2% |

> 0.5% |

| Corrosion Rate in Molten Glass (mm/year) |

0.12 |

0.35 |

| Service Life in Glass Furnace (months) |

18 - 24 |

10 - 14 |

| Defect Rate Reduction |

Up to 25% |

- |

Tailored Solutions for Diverse Customer Requirements

Different glass manufacturers prioritize diverse operational parameters. Premium silica brick suppliers offer customized solutions to address:

- Quality-Driven Clients: Emphasis on maximum glass purity and minimal contamination paired with enhanced furnace longevity.

- Cost-Sensitive Clients: Offers balance between upfront material costs and extended service intervals to optimize total cost of ownership.

This flexibility empowers clients to select silica brick grades precisely aligned with their production goals, contributing directly to lowered defect rates and decreased maintenance downtime.

Driving Efficiency Across the Glass Manufacturing Process

By incorporating premium silica bricks, glass producers can achieve:

- Lowered defective product rates by up to 25% due to reduced contamination and improved furnace stability.

- Extended refractory lifespan, reducing the frequency—and associated costs—of furnace shutdowns.

- Enhanced glass batch consistency, contributing to higher end-product quality and customer satisfaction.

- Reduced energy consumption attributed to superior thermal insulation properties.

These benefits collectively drive down operational costs while elevating product standards, providing a strategic competitive edge.