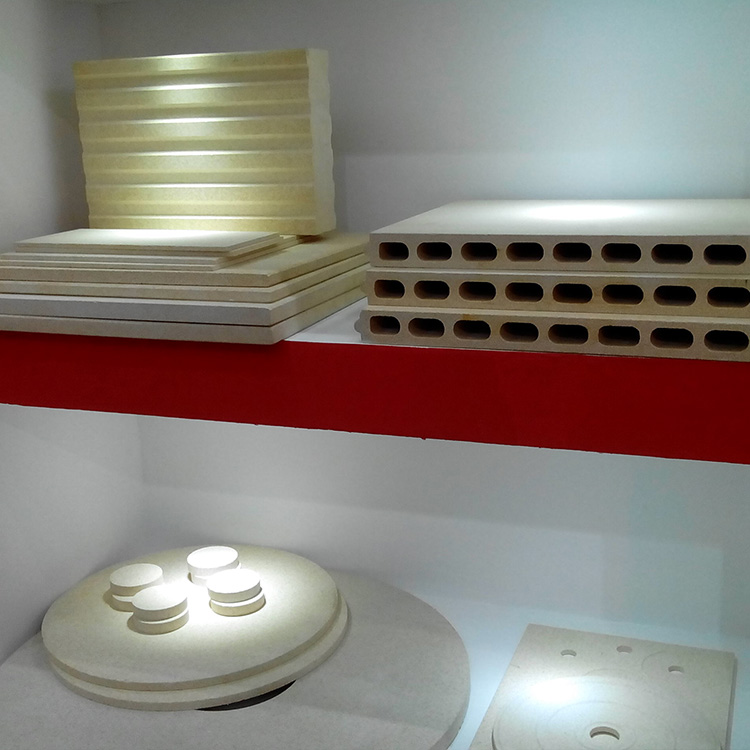

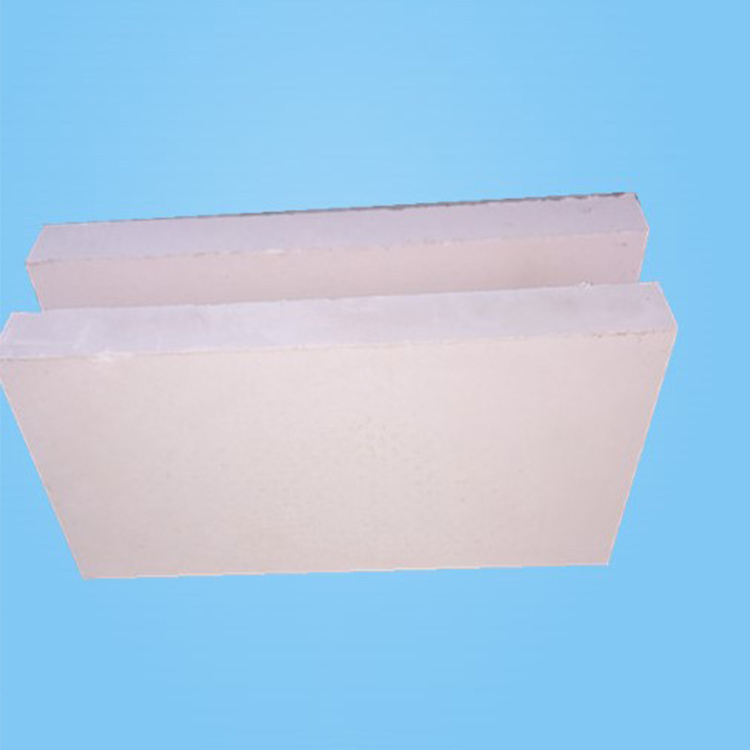

In the highly specialized industry of glass manufacturing, the choice of refractory materials directly impacts kiln stability and glass quality. High-purity silica bricks, boasting SiO2 content exceeding 96%, have emerged as pivotal components in the construction of high-temperature zones within glass furnaces. This article delves into the technical nuances and practical benefits of using these advanced silica bricks, highlighting their exceptional resistance to chemical corrosion and superior ability to maintain molten glass purity.

The cornerstone of superior silica bricks is their raw material: natural silica sand with a SiO2 purity of over 96%. This high silica content translates into enhanced thermal stability, enabling the bricks to withstand temperatures upwards of 1650°C without significant structural degradation. Compared to standard silica bricks, which typically have around 90–92% SiO2, the high-purity variant shows reduced volume expansion—down by approximately 30%—which mitigates crack formation under thermal cycling.

| Property | High SiO2 Brick | Standard Silica Brick |

|---|---|---|

| SiO2 Content | > 96% | 90-92% |

| Maximum Operating Temperature | ~1650°C | ~1550°C |

| Volume Expansion on Heating | < 0.1% | ~0.15% |

| Density | 1.8 - 2.0 g/cm³ | 2.0 - 2.2 g/cm³ |

High SiO2 content bricks demonstrate exceptional resistance to the corrosive atmosphere inside glass furnaces, where molten glass and various gaseous byproducts aggressively challenge refractory linings. The increased silica purity greatly reduces dissolution rates in molten glass, preventing contamination and maintaining glass purity. Industry field tests indicate that furnaces retrofitted with high-purity silica bricks experience up to a 25% reduction in chemical corrosion-related wear compared to conventional bricks.

By minimizing chemical interactions between refractory material and molten glass, high SiO2 bricks help maintain the chemical integrity of the glass melt. This translates directly into fewer impurities and discolorations in the final product, boosting the glass yield rate by an average of 8-12% in documented cases. For example, a prominent glass manufacturing plant in Germany reported a drop in defective glass parts from 4.5% to 1.7% after adopting these advanced bricks.

Furthermore, the outstanding volume stability of these bricks reduces maintenance interventions and downtime. Furnaces benefit from extended campaign lives, with maintenance intervals lengthened by up to 30%, leading to significant cost savings and improved overall productivity.

Whether the operational focus is on maximizing glass quality or minimizing operational costs, high SiO2 silica bricks offer flexible advantages aligned with these priorities. Customers valuing superior glass finish appreciate the minimal contamination effects, while cost-conscious operators gain from the reduced frequency of refractory replacements and lower energy consumption due to optimized thermal profiles.