In the glass kiln industry, the choice of refractory materials is crucial for ensuring long - term stable operation and product quality. High SiO₂ content silica bricks have emerged as a game - changer, offering remarkable advantages in enhancing the high - temperature resistance of glass kilns. This article delves into the key components of these silica bricks and how they contribute to the improved performance of glass kilns.

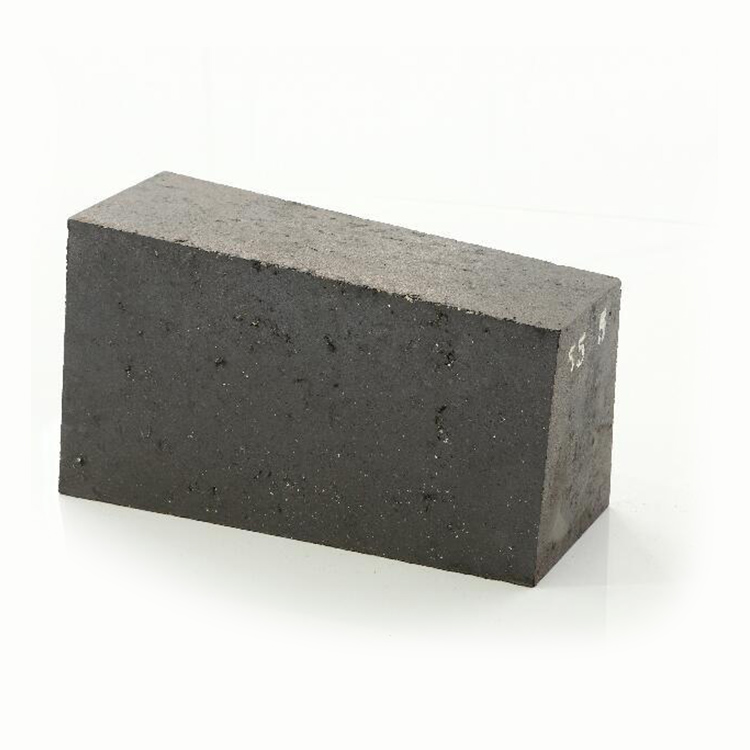

Silica bricks for glass kilns are primarily composed of natural silica sand with a SiO₂ content of over 96%, along with tridymite and cristobalite. According to industry reports, this high - purity composition is the foundation for the excellent properties of silica bricks. The high SiO₂ content not only provides superior heat resistance but also endows the bricks with unique physical and chemical characteristics.

Experimental data shows that the high SiO₂ content in silica bricks significantly enhances their ability to withstand high temperatures. In a series of tests, silica bricks with a SiO₂ content of 96% or more could maintain their structural integrity at temperatures up to 1600°C. This high - temperature stability is essential for glass kilns, which often operate at extremely high temperatures. The high - temperature resistance of these silica bricks ensures that the glass kiln can operate continuously without significant damage to the refractory lining.

One of the critical properties of high SiO₂ content silica bricks is their high - temperature volume stability. During the heating and cooling cycles in a glass kiln, most materials tend to expand and contract, which can lead to cracking and damage to the kiln lining. However, silica bricks with a high SiO₂ content have minimal volume changes at high temperatures. Industry - wide verifications have shown that the volume change rate of these silica bricks is less than 1% within the operating temperature range of glass kilns. This stability ensures the long - term integrity of the glass kiln structure and reduces the need for frequent repairs and replacements.

In a glass kiln, the refractory materials are exposed to various chemical substances, including molten glass, fluxes, and combustion products. High SiO₂ content silica bricks exhibit excellent chemical corrosion resistance. A customer case study revealed that in a glass manufacturing plant, after using these silica bricks for five years, the corrosion depth of the bricks was less than 5mm, while traditional refractory materials showed significant corrosion and needed to be replaced within two years. This chemical corrosion resistance not only extends the service life of the glass kiln but also prevents the contamination of the glass melt, ensuring the high quality of the final glass products.

Another advantage of high SiO₂ content silica bricks is their lightweight nature. Compared with some traditional refractory materials, these silica bricks are about 20% lighter. This lightweight feature reduces the overall weight of the glass kiln structure, which can save on construction costs and energy consumption during operation. Additionally, it makes the installation and maintenance of the kiln easier and more efficient.

Many glass kiln operators have witnessed the benefits of using high SiO₂ content silica bricks. For example, a large - scale glass manufacturing company in Europe replaced its old refractory lining with these silica bricks. After the replacement, the kiln's operating efficiency increased by 15%, and the energy consumption decreased by 12%. The company also reported a significant improvement in the quality of its glass products due to the reduced contamination from the refractory materials.

In conclusion, high SiO₂ content silica bricks offer a comprehensive solution for enhancing the high - temperature resistance, stability, and chemical corrosion resistance of glass kilns. Their unique composition and excellent properties make them an ideal choice for glass kiln operators. If you are a decision - maker or purchaser in the glass kiln industry, don't miss the opportunity to upgrade your kiln with these advanced silica bricks. Click here to learn more about our high - quality glass kiln silica bricks and take your glass manufacturing business to the next level!

We encourage you to share your thoughts, experiences, or questions about high SiO₂ content silica bricks in the comments section below. Your input will not only help us improve our content but also contribute to the knowledge exchange in the glass kiln industry.