Refractory materials play a critical role in high-temperature industrial processes such as steelmaking, glass manufacturing, and cement production. The performance of these materials directly affects operational efficiency, equipment lifespan, and overall cost-effectiveness. In this article, we explore the unique properties and advantages of high-temperature magnesia-chrome bricks, a high-performance refractory material that has gained widespread recognition in global industries.

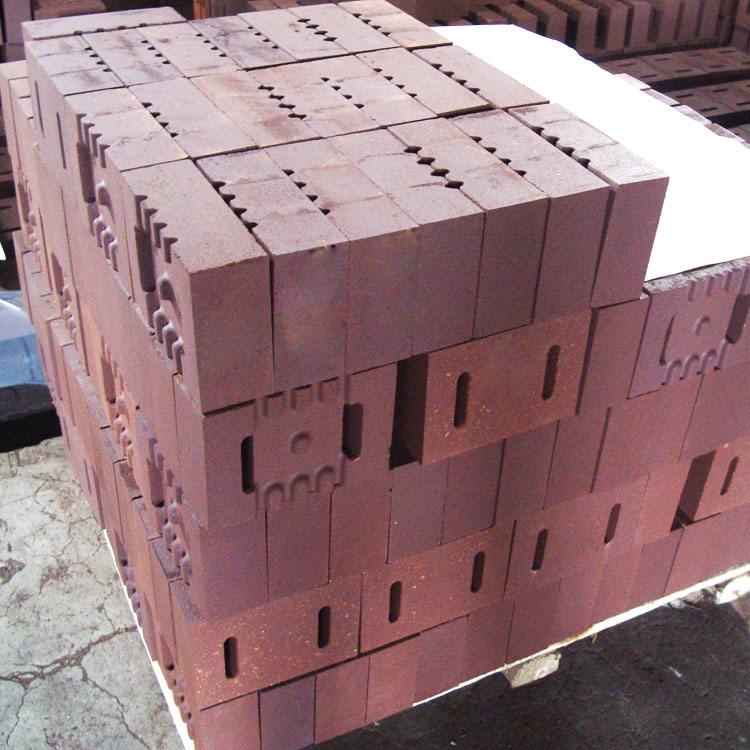

High-temperature magnesia-chrome bricks are produced using sintered magnesite and refractory-grade chromite ore as primary raw materials, bonded together with silicate binders. This combination results in a refractory product that exhibits exceptional strength, thermal stability, and resistance to chemical corrosion.

The sintered magnesite provides excellent thermal conductivity and high melting point, while the refractory-grade chromite ore enhances the brick's resistance to slag and molten metal. The silicate bonding system ensures strong interparticle adhesion, contributing to the brick’s durability under extreme conditions.

Compared to traditional magnesia bricks, high-temperature magnesia-chrome bricks offer superior performance in several key areas:

| Property | Magnesia-Chrome Bricks | Magnesia Bricks |

|---|---|---|

| Compression Strength (MPa) | 65-75 | 45-55 |

| Thermal Conductivity (W/m·K) | 1.2-1.5 | 0.8-1.0 |

| Resistance to Slag Corrosion | Excellent | Good |

| Thermal Shock Resistance | High | Moderate |

High-temperature magnesia-chrome bricks have been successfully applied in various industrial sectors, delivering measurable benefits:

.jpg)

These applications demonstrate the versatility and reliability of high-temperature magnesia-chrome bricks across different industrial environments.

Our high-temperature magnesia-chrome bricks are manufactured to meet international standards, ensuring consistent quality and performance. With a melting point exceeding 2000°C and a compressive strength of up to 75 MPa, they are designed to withstand the harshest industrial conditions.

Whether you're operating in steel mills, glass plants, or other high-temperature facilities, our refractory solutions can help you achieve better efficiency, longer service life, and reduced maintenance costs.

Don’t miss the opportunity to upgrade your refractory systems with high-performance magnesia-chrome bricks. Contact us today to request a sample or schedule a consultation. Let us help you optimize your operations and stay ahead in the competitive industrial market.

Request a Sample or Consultation