In high-temperature industrial operations, the role of refractory materials cannot be overstated. These materials are the backbone of processes where extreme heat is involved, such as steelmaking, glass manufacturing, and cement production. The performance of refractory materials directly impacts the efficiency, safety, and cost-effectiveness of these operations. Poorly performing refractory materials can lead to frequent replacements, production downtime, and increased costs. Among the various refractory materials available, high-temperature magnesia-chrome bricks stand out as a remarkable option.

High-temperature magnesia-chrome bricks are crafted from carefully selected raw materials. The primary components are sintered magnesia and refractory-grade chrome ore. Sintered magnesia is known for its high melting point, excellent thermal stability, and strong resistance to basic slag. Refractory-grade chrome ore, on the other hand, enhances the brick's resistance to corrosion and oxidation. The manufacturing process involves mixing these raw materials with a silicate binder. After thorough mixing, the mixture is pressed into the desired brick shape and then fired at high temperatures. This firing process further strengthens the structure of the bricks, ensuring their performance under extreme conditions.

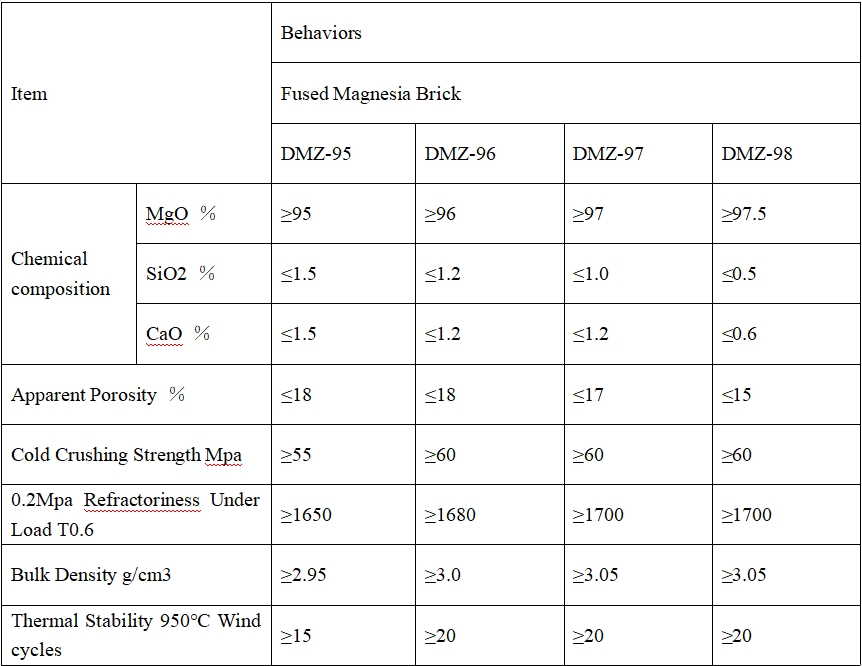

To understand the superiority of high-temperature magnesia-chrome bricks, let's compare them with magnesia bricks. Magnesia bricks are also widely used in high-temperature applications, but they have some limitations when compared to magnesia-chrome bricks. The following table presents a detailed comparison based on several key performance indicators:

| Performance Indicator | High-Temperature Magnesia-Chrome Bricks | Magnesia Bricks |

|---|---|---|

| Compressive Strength | Up to 60 MPa | Around 40 MPa |

| Corrosion Resistance | Highly resistant to acidic and basic slags | Good resistance to basic slags, less resistant to acidic slags |

| Thermal Shock Resistance | Can withstand up to 20 thermal cycles | Can withstand up to 10 thermal cycles |

As shown in the table, high-temperature magnesia-chrome bricks have a significant advantage in terms of compressive strength, corrosion resistance, and thermal shock resistance. This makes them a better choice for applications where the materials are exposed to harsh conditions, such as frequent temperature changes and corrosive environments.

High-temperature magnesia-chrome bricks have been widely used in various industries. In the steelmaking industry, they are used in the lining of electric arc furnaces and converters. The high compressive strength and corrosion resistance of these bricks ensure a longer service life of the furnace lining, reducing the frequency of repairs and replacements. In the glass manufacturing industry, magnesia-chrome bricks are used in the regenerators and melting tanks. Their excellent thermal stability and resistance to thermal shock help maintain a stable operating environment, improving the quality of the glass products.

In conclusion, high-temperature magnesia-chrome bricks offer superior performance compared to magnesia bricks. Their high strength, excellent corrosion resistance, and good thermal shock resistance make them an ideal choice for high-temperature applications. If you are currently considering refractory materials for your industrial operations, we invite you to explore the benefits of our high-temperature magnesia-chrome bricks. Contact us today at [Contact Email] or visit our website [Website URL] to learn more and request a free sample.

Don't miss out on the opportunity to enhance your high-temperature operations. Click here to visit our website and request a free sample of our high-temperature magnesia-chrome bricks.