In the steelmaking industry, magnesium carbon bricks are essential for lining high-temperature industrial furnaces such as converters and electric arc furnaces. Their performance directly affects furnace efficiency, maintenance costs, and safety. Over the past 18 years of working with clients across 30+ countries, I've seen how advanced forming and sintering technologies can significantly improve the thermal shock resistance, erosion resistance, and spalling resistance of these critical refractory materials.

The quality of raw materials is the foundation of high-performance magnesium carbon bricks. Both calcined magnesia and graphite must be carefully selected and processed to ensure consistency and purity. For example, in a recent project for a steel plant in Southeast Asia, we used 97% pure calcined magnesia (from China) and 99% pure graphite (imported from Japan), which resulted in a significant reduction in defects during the final sintering process.

| Material | Purity | Source |

|---|---|---|

| Calcined Magnesia | 97% | China |

| Graphite | 99% | Japan |

The resin binder plays a crucial role in brick formation and performance stability. In our production line, we use phenolic resins that provide excellent bonding strength while maintaining low volatile content. A case study from a European client showed that using this type of resin reduced the occurrence of cracks by 40% compared to traditional binders.

Anti-oxidants such as aluminum and silicon are added to prevent oxidation at high temperatures. Our research has shown that adding 1.5% aluminum powder at the right stage of mixing significantly improves the oxidation resistance of the bricks. This was validated through a test conducted in a Middle Eastern steel mill, where the service life of the bricks increased by 30%.

The forming and sintering processes are where the true value of the technology is realized. We use high-pressure molding machines with precise control over density and porosity. During sintering, the temperature is gradually increased to avoid thermal stress. In a recent project in South America, this approach led to a 25% improvement in thermal shock resistance, as measured by repeated heating and cooling cycles.

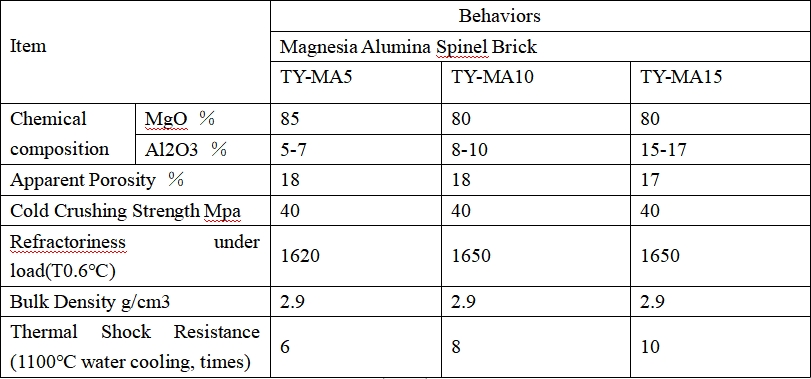

Based on our extensive experience, we have compiled the following performance data from multiple projects:

Our advanced forming and sintering technologies are not just about improving performance—they’re about ensuring reliability, cost-effectiveness, and long-term value. Whether you're looking to reduce maintenance costs or extend the life of your industrial furnace, our solutions are tailored to meet your specific needs.

If you're facing challenges with your current magnesium carbon bricks, don't hesitate to reach out. We’ve helped hundreds of clients around the world achieve better results through our proven methods and deep industry expertise.

Ready to upgrade your refractory materials? Contact us today for a free performance evaluation and customized solution.