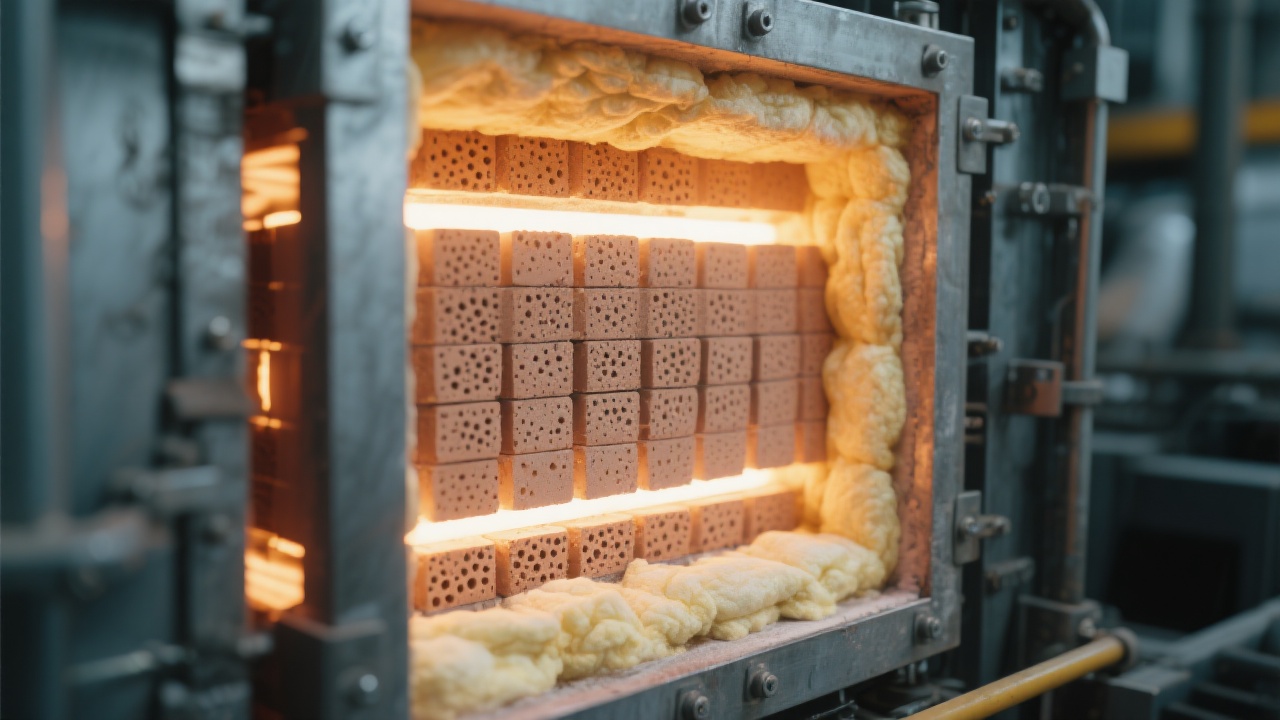

In the industrial landscape, kilns play a pivotal role in various manufacturing processes, from cement production to steelmaking. However, one of the most persistent challenges faced by these kilns is the erosion caused by alkaline slag. This issue not only shortens the lifespan of kiln equipment but also leads to increased maintenance costs and reduced production efficiency. In this context, synthetic forsterite bricks have emerged as a promising solution, offering exceptional resistance to alkaline slag erosion and high - temperature wear.

Synthetic forsterite bricks are composed of a unique combination of sintered forsterite, serpentine, and periclase. Each of these components plays a crucial role in enhancing the brick's performance.

Forsterite (Mg₂SiO₄) is the main crystalline phase in these bricks. It has a high melting point of about 1890°C, which provides excellent high - temperature stability. The crystal structure of forsterite is relatively stable, and it can effectively resist the penetration and erosion of alkaline slag. Serpentine, on the other hand, contains a certain amount of water of crystallization. During the heating process, the water of crystallization is released, which not only helps to reduce the thermal stress of the bricks but also forms a certain amount of pores. These pores can absorb some of the energy generated during the slag erosion process, thereby protecting the internal structure of the bricks. Periclase (MgO) has strong basicity and can react with acidic components in the slag to form a dense protective layer on the surface of the bricks, further enhancing the resistance to alkaline slag erosion.

The resistance of synthetic forsterite bricks to alkaline slag and high - temperature erosion is based on a combination of physical and chemical mechanisms. Physically, the dense structure of the bricks reduces the penetration rate of slag. The high - strength crystal structure of forsterite and periclase can withstand the mechanical stress caused by high - temperature and slag flow. Chemically, as mentioned before, periclase can react with acidic components in the slag, such as SiO₂ and Al₂O₃, to form compounds with high melting points, such as magnesium silicate and magnesium aluminate. These compounds form a protective layer on the surface of the bricks, preventing further erosion of the slag.

Let's take a look at some real - world applications of synthetic forsterite bricks in different industries.

In a large - scale cement plant, the traditional refractory bricks in the kiln had an average lifespan of about 6 months. The high - temperature and alkaline environment in the cement kiln led to severe erosion of the bricks, resulting in frequent shutdowns for maintenance. After replacing the traditional bricks with synthetic forsterite bricks, the lifespan of the kiln lining increased to 18 months. This not only reduced the maintenance frequency but also increased the annual production capacity by about 15% due to fewer shutdowns.

In a steelmaking plant, the ladle lining made of traditional refractory materials had a high erosion rate. The cost of replacing the lining was quite high, and it also affected the quality of the steel due to the possible contamination from the eroded refractory. By using synthetic forsterite bricks, the erosion rate decreased by about 50%. The cost of lining replacement was reduced by 30%, and the quality of the steel improved as well.

| Parameters | Synthetic Forsterite Bricks | Traditional Refractory Bricks |

|---|---|---|

| Lifespan | 18 - 24 months (in most cases) | 6 - 12 months |

| Erosion Rate | About 50% lower than traditional bricks | Higher |

| Maintenance Cost | Reduced by 30 - 50% | Higher |

| Environmental Impact | Lower due to longer lifespan and less waste generation | Higher |

As shown in the table, synthetic forsterite bricks have significant advantages over traditional refractory materials in terms of lifespan, erosion resistance, maintenance cost, and environmental impact.

Synthetic forsterite bricks offer a reliable and cost - effective solution for kiln operators facing the challenges of alkaline slag erosion. With their unique composition, excellent technical principles, and proven performance in real - world applications, these bricks can effectively extend the lifespan of kilns, reduce maintenance costs, and improve production efficiency. If you are looking for a high - performance refractory material for your kiln, consider synthetic forsterite bricks. Learn more about synthetic forsterite brick technology details, contact experts for consultation, and help your kiln operate stably.

Do you have similar problems in your industry? Share your specific scenarios, and we'll send you three solution cases from the same industry.