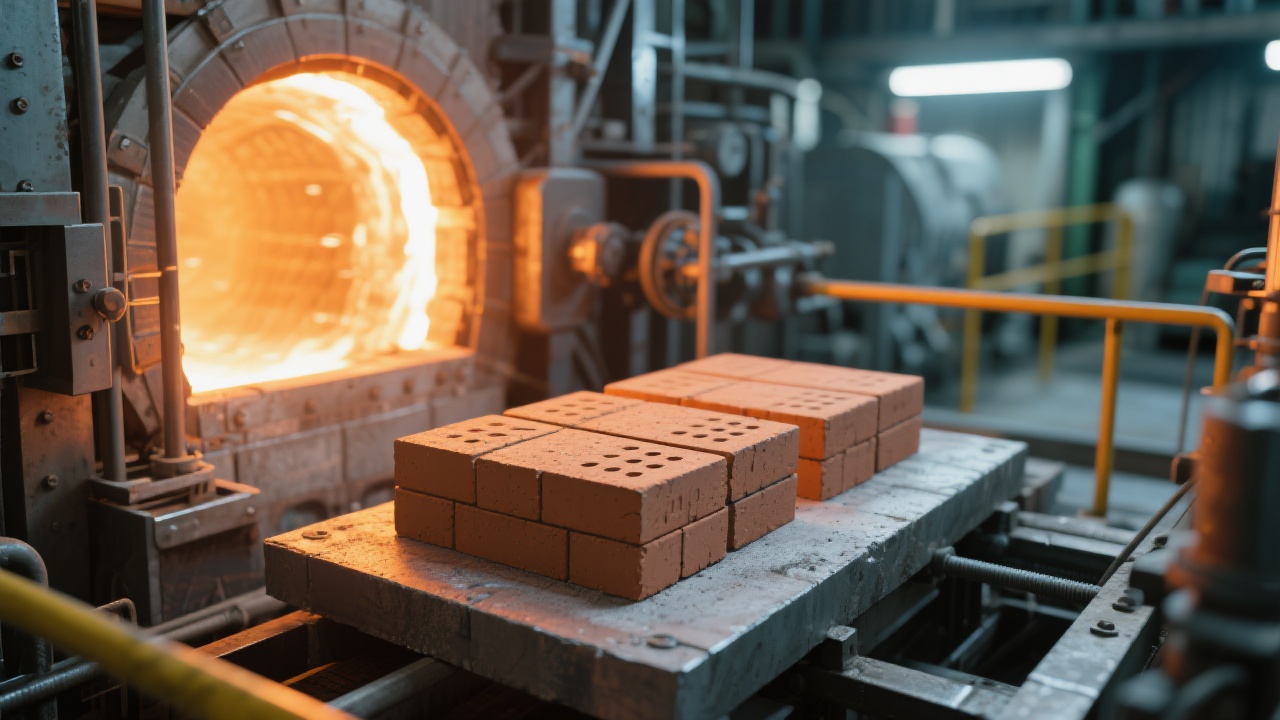

In the glass manufacturing industry, glass furnaces are at the heart of the production process. However, they are currently facing significant environmental pressures. Traditional refractory materials, such as magnesia-chrome bricks, have long been used in glass furnaces. But they come with certain limitations. Magnesia-chrome bricks can release hexavalent chromium during high - temperature use, which is a highly toxic substance that poses a serious threat to the environment and human health. In addition, with the increasing strictness of environmental regulations around the world, the use of magnesia - chrome bricks is gradually being restricted.

Synthetic forsterite bricks are mainly composed of sintered olivine, serpentine, and periclase. At high temperatures, these components interact with each other to form a stable structure. The sintered olivine has excellent high - temperature stability and can provide a strong framework for the brick. Serpentine can react with other components during the heating process, filling the gaps in the structure and enhancing the density of the brick. Periclase can improve the high - temperature strength of the brick.

The principle of forming a stable structure at high temperatures can be understood as follows: Just like building a house, sintered olivine is like the main beams and columns, providing the basic framework. Serpentine is like the cement that fills the gaps between the bricks, making the whole structure more compact. Periclase is like the steel bars in the concrete, enhancing the strength of the structure. In a previous project for a European glass manufacturer, by analyzing the structure of synthetic forsterite bricks after high - temperature use, it was found that they maintained a stable structure, which ensured the long - term performance of the bricks in the furnace.

Alkaline slag erosion is one of the main problems faced by glass furnaces. Synthetic forsterite bricks have excellent resistance to alkaline slag erosion. From a microscopic perspective, the crystal structure of synthetic forsterite bricks can prevent the penetration of alkaline slag ions. When alkaline slag comes into contact with the brick surface, the stable crystal structure can block the diffusion of ions, reducing the chemical reaction between the slag and the brick.

In a laboratory experiment, samples of synthetic forsterite bricks and magnesia - chrome bricks were placed in an alkaline slag environment at 1500°C for 100 hours. After the experiment, it was found that the erosion depth of synthetic forsterite bricks was only 2 - 3 mm, while that of magnesia - chrome bricks was 5 - 7 mm. This shows that synthetic forsterite bricks have significantly better resistance to alkaline slag erosion.

Synthetic forsterite bricks are non - toxic and harmless. They do not release harmful substances during high - temperature use, which is in line with the current environmental protection policy orientation and market demand. In addition, the production process of synthetic forsterite bricks has lower emissions compared to magnesia - chrome bricks. This not only helps glass manufacturers meet environmental requirements but also enhances their corporate image in terms of environmental protection.

| Indicator | Synthetic Forsterite Bricks | Magnesia - Chrome Bricks |

|---|---|---|

| Resistance to Alkaline Slag Erosion | Excellent, erosion depth 2 - 3 mm in experiment | Good, erosion depth 5 - 7 mm in experiment |

| Environmental Impact | Non - toxic, low - emission | May release hexavalent chromium |

| Cost | Slightly higher initial cost, but lower long - term cost due to longer service life | Lower initial cost, but higher long - term cost due to shorter service life |

A glass factory in Asia replaced magnesia - chrome bricks with synthetic forsterite bricks in its glass furnace. After six months of use, the maintenance frequency of the furnace decreased by 30%. After one year, the service life of the furnace was extended by about 20% compared to the previous use of magnesia - chrome bricks. This not only saved a lot of maintenance costs but also increased the production efficiency of the factory.

You may be wondering, "Is it really worth the investment to replace magnesia - chrome bricks with synthetic forsterite bricks?" The answer is yes. Synthetic forsterite bricks offer not only better performance but also significant environmental benefits. They are not just a replacement for magnesia - chrome bricks; they represent a leap in efficiency and environmental protection.

Are you currently considering an environmental upgrade for your glass furnace? Let every brick be a witness to your environmental upgrade. Click here to learn more about how synthetic forsterite bricks can transform your glass furnace and provide you with a scientific basis for your furnace transformation decision - making.