High-temperature environments are common in industrial settings such as steelmaking, glass production, and cement manufacturing. In these conditions, refractory materials play a critical role in maintaining equipment integrity, operational efficiency, and safety. Selecting the right material is not just about durability—it’s about ensuring long-term performance and cost-effectiveness.

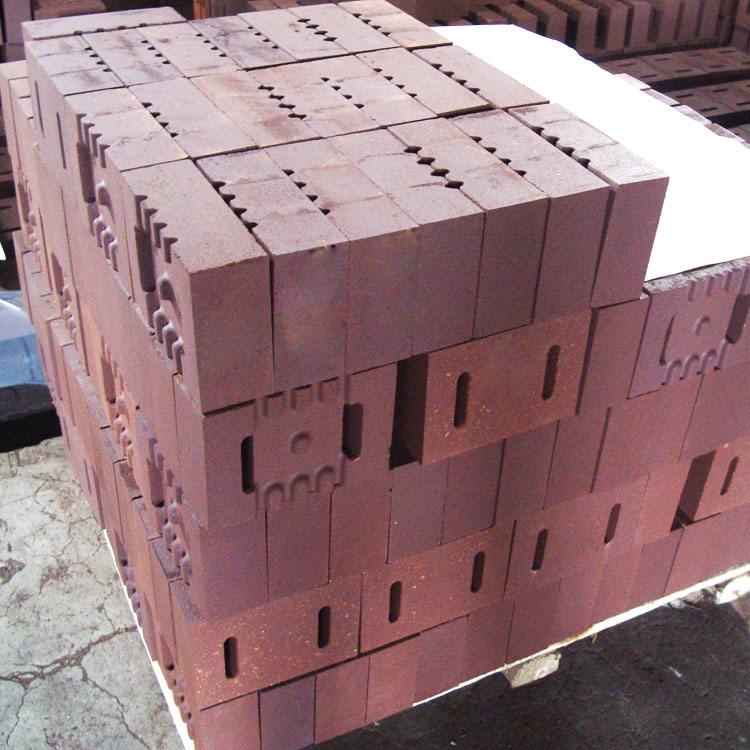

Among the many options available, high-temperature magnesia-chrome bricks stand out as a top choice for their exceptional properties. These bricks are made from sintered magnesite and high-purity chromite ore, bonded with silicate binders to form a dense, high-performance refractory material. Their ability to withstand extreme temperatures and harsh chemical environments makes them ideal for demanding applications.

The quality of magnesia-chrome bricks starts with the raw materials. Sintered magnesite provides high thermal stability and resistance to alkali attack, while chromite ore contributes to excellent corrosion resistance. The combination of these two materials, along with advanced silicate bonding technology, ensures that the final product has superior structural integrity and thermal shock resistance.

The manufacturing process involves precise mixing, pressing, and sintering at high temperatures. This results in a dense microstructure that minimizes porosity and enhances mechanical strength. The final product is then tested for its physical and chemical properties to ensure it meets industry standards.

Compared to traditional refractories like fireclay or silica bricks, magnesia-chrome bricks offer significant advantages:

| Property | Magnesia-Chrome Brick | Fireclay Brick | Silica Brick |

|---|---|---|---|

| Max Service Temperature | Over 2000°C | 1350–1500°C | 1400–1550°C |

| Highest Load Softening Point | 1550°C+ | 1200–1350°C | 1300–1450°C |

| Thermal Shock Resistance | Excellent | Good | Poor |

| Corrosion Resistance | Very High | Moderate | Low |

Magnesia-chrome bricks have been successfully used in various high-temperature industrial applications. Here are some examples:

One leading steel plant in Southeast Asia reported a 30% increase in furnace lifespan after switching to magnesia-chrome bricks, significantly reducing downtime and operational costs.

When it comes to refractory solutions for high-temperature applications, magnesia-chrome bricks offer a proven combination of performance, durability, and cost-efficiency. Their ability to handle extreme thermal loads, resist chemical erosion, and maintain structural integrity under repeated heating and cooling cycles makes them a preferred choice across multiple industries.

If you're looking for a reliable and high-performing refractory solution, we invite you to explore our range of magnesia-chrome bricks. Our team is ready to provide technical support, customized solutions, and competitive pricing tailored to your specific needs.