In the industrial furnace industry, magnesia carbon bricks have emerged as a highly efficient refractory material. This article delves into the secrets of their efficient production process, exploring how every step impacts the performance of these bricks.

The quality of raw materials is the cornerstone of high - performance magnesia carbon bricks. Strict selection and scientific treatment methods are employed. For instance, reburned or fused magnesia and graphite are carefully chosen. The purity of magnesia should be above 95%, and the fixed carbon content in graphite should be no less than 90%. A case study of a well - known industrial furnace manufacturer showed that by using high - quality magnesia with a purity of 97% and graphite with a 92% fixed carbon content, the service life of magnesia carbon bricks in their converters increased by 15% compared to using lower - quality raw materials.

Binder resin plays a crucial role in the forming and performance of magnesia carbon bricks. It provides the necessary adhesion for the brick body during the manufacturing process. The resin should have good thermal stability and carbon residue rate. Generally, a resin with a carbon residue rate of around 40% - 50% is preferred. When adding the resin, the mixing time and temperature need to be precisely controlled. In a certain production plant, by optimizing the resin addition process and using a resin with a 45% carbon residue rate, the strength of the magnesia carbon bricks increased by 12%.

Antioxidants are added to enhance the oxidation resistance of magnesia carbon bricks. The appropriate addition time and proportion are vital. Commonly used antioxidants include aluminum powder and silicon powder. Usually, the addition amount of antioxidants is about 3% - 5% of the total mass of the raw materials. In an industrial application, a steel plant added 4% aluminum powder as an antioxidant to the magnesia carbon bricks in their electric arc furnaces. As a result, the oxidation rate of the bricks decreased by 20%, significantly improving their service life.

Advanced forming technology and refined firing processes ensure that magnesia carbon bricks have excellent thermal shock stability, corrosion resistance, and spalling resistance. For example, isostatic pressing technology can make the internal structure of the bricks more uniform. During the firing process, the temperature and heating rate are precisely controlled. A company adopted a new - type firing process, which increased the thermal shock resistance of the magnesia carbon bricks by 25%, making them more suitable for harsh industrial furnace environments.

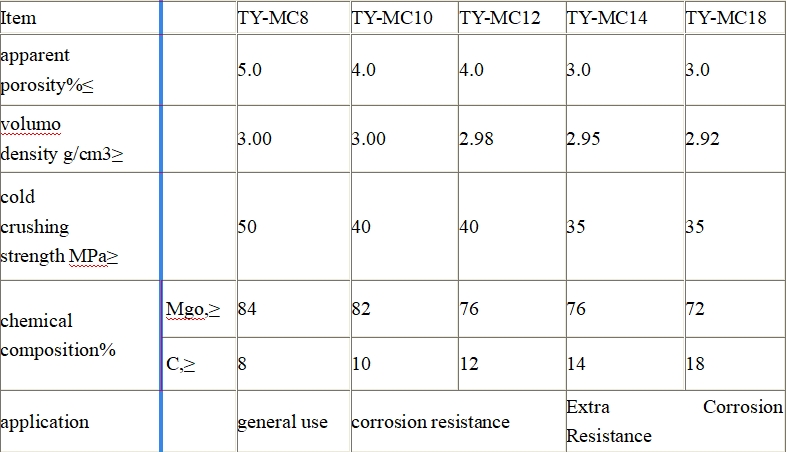

Our company has unique advantages in the production of magnesia carbon bricks. We have introduced advanced production equipment and innovative technologies. Compared with traditional production methods, our production efficiency has increased by 30%, and the product qualification rate has reached 98%. The following table shows the comparison between our products and traditional products:

| Product Features | Our Products | Traditional Products |

|---|---|---|

| Service Life | 15% - 20% longer | Normal |

| Strength | 10% - 15% higher | Normal |

| Oxidation Resistance | 20% better | Normal |

Our innovative production technology not only improves product performance but also reduces energy consumption during production. We are committed to providing high - quality magnesia carbon bricks to meet the diverse needs of industrial furnace users.

If you are an industrial furnace user or a technical professional interested in refractory materials, we invite you to learn more about our high - performance magnesia carbon bricks. With our unique production process and excellent product performance, we are confident to be your ideal partner. Click here to explore more details and contact us!

Do you have any questions or experiences related to magnesia carbon bricks? Share your thoughts in the comments below, and we'll be happy to discuss with you!