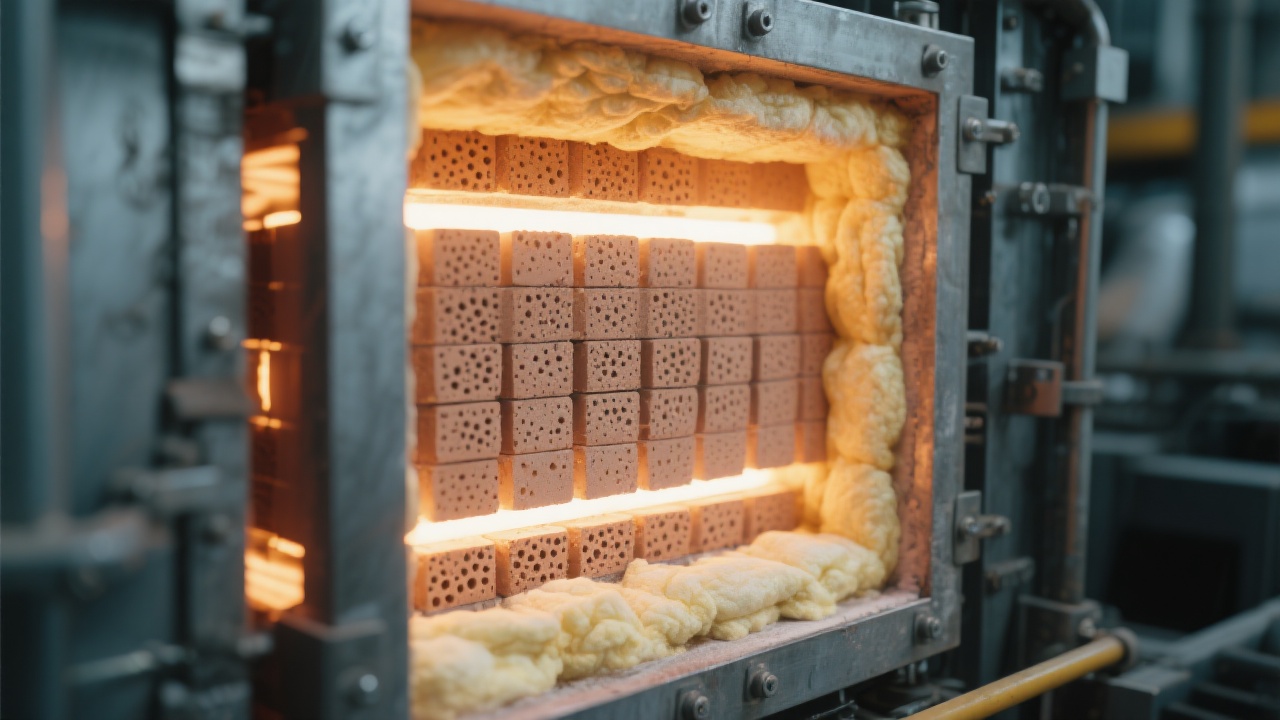

In high-temperature industrial processes such as glass manufacturing and non-ferrous metal metallurgy, the choice of refractory materials plays a pivotal role in ensuring operational efficiency and minimizing downtime. Inferior refractory products often lead to premature failure, costly maintenance, and process instability. Against this backdrop, magnesia-zirconia (MgO-ZrO2 ) bricks have emerged as a leading solution due to their remarkable chemical and thermal properties tailored to withstand severe alkali slags and corrosive environments.

Magnesia-zirconia bricks are primarily composed of fused magnesia (MgO) and fused zirconia (ZrSiO4 ), which contribute to their exceptional performance in aggressive high-temperature settings. The fused magnesia provides high basicity and resistance to alkaline slags, while fused zirconia enhances mechanical strength and resistance to thermal shock. The synergy of these raw materials results in a dense microstructure with minimal porosity, translating into superior resistance against slag penetration and chemical erosion.

| Property | Magnesia-Zirconia Brick | Traditional Magnesia Brick |

|---|---|---|

| Bulk Density (g/cm³) | 3.45 - 3.55 | 3.30 - 3.40 |

| Cold Crushing Strength (MPa) | ≥ 45 | 35 - 40 |

| Resistance to Alkali Slag (mm penetration) | ≤ 3 | ≥ 6 |

| Maximum Service Temperature (°C) | ~1800 | ~1750 |

These parameters are supported by extensive laboratory evaluations and onsite monitoring. The enhanced density and microstructural integrity limit the penetration and chemical attack by molten slag, a critical challenge in both glass furnaces exposed to volatile alkali vapors and metallurgical units handling aggressive non-ferrous slags.

Glass Furnace Industry: A leading glass manufacturer in Southeast Asia reported recurrent premature wear of their furnace crowns and sidewalls using conventional magnesia bricks. Upon switching to magnesia-zirconia bricks, the service life improved by over 35%, reducing unplanned downtimes by nearly 20%. The bricks withstood the harsh alkali-rich environment caused by sodium and potassium vapors, maintaining structural integrity and dimensional stability even after 18 months of continuous operation.

Customer Feedback: “Since integrating magnesia-zirconia bricks, our maintenance intervals have extended considerably, and energy consumption has stabilized due to better insulation performance.” – Operations Manager, GlassWorks Co.

Non-Ferrous Metallurgy: In the copper smelting sector of South America, furnaces lined with traditional magnesia bricks suffered from frequent chemical corrosion caused by complex slag compositions rich in chlorides and oxidizers. The introduction of magnesia-zirconia bricks led to a 40% extension in lining lifecycle, alongside a 15% reduction in refractory repair costs within the first year. The bricks’ enhanced resistance to molten slag intrusion minimized shell thinning and structural failures.

Industry Expert Insight: “The coupling of electric fusion technology with zirconia incorporation has significantly elevated the durability of magnesia bricks in highly corrosive smelting environments.” – Senior Metallurgical Consultant

Although magnesia-zirconia bricks entail a higher initial investment — typically around 15-20% above standard magnesia bricks — the overall cost of ownership is substantially lower. This stems from their prolonged service life, reduced frequency of maintenance shutdowns, and improved process stability.

| Cost Aspect | Magnesia-Zirconia Brick | Conventional Magnesia Brick |

|---|---|---|

| Initial Purchase Price | High | Medium |

| Service Life | Up to 18 months or more | 12 months or less |

| Maintenance Frequency | Lower | Higher |

| Overall Operational Costs | Reduced by up to 15% | Standard |

Ultimately, the decision to adopt magnesia-zirconia bricks should align with your plant’s core priorities — whether emphasizing maximum uptime, operational stability, or long-term cost savings.

In summary, magnesia-zirconia bricks offer an advanced refractory solution distinguished by superior chemical resistance, mechanical robustness, and thermal stability. Their proven track record in glass furnace and non-ferrous metallurgical applications underlines their value in extending service life, minimizing unplanned downtime, and enhancing overall process economics.

For enterprises striving to boost furnace reliability and operational efficiency, magnesia-zirconia bricks represent an investment with tangible returns.