Glass kilns in the current industry are facing several significant challenges. High - temperature deformation is a common issue. When the kiln is exposed to extreme heat for long periods, the structure may warp, leading to uneven heating and potential problems in the glass - forming process. There is also a risk of glass liquid contamination, which can severely affect the quality of the final glass products. Additionally, the high maintenance costs associated with these problems are a burden on glass manufacturers. These issues not only reduce production efficiency but also increase the overall cost of glass production.

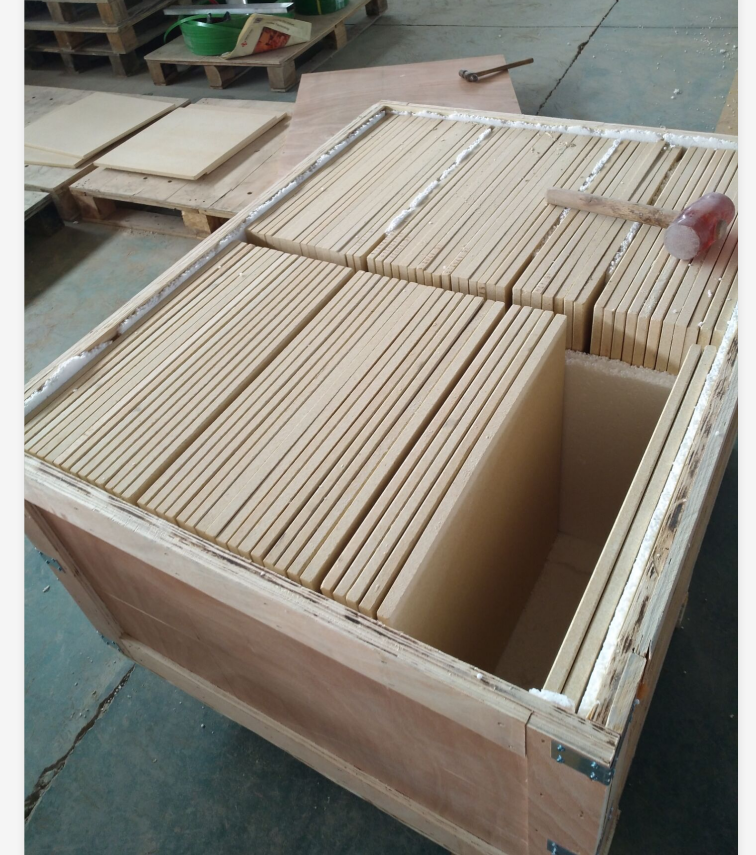

The performance of silica bricks for glass kilns is closely related to their raw materials and structure. The proportion of tridymite and cristobalite in the silica brick structure plays a crucial role. These crystal forms contribute to the high - temperature performance of the silica bricks. The content of SiO₂ is a key factor. High - purity SiO₂ (above 96%) is the core of high - performance silica bricks. The high SiO₂ content enhances the high - temperature volume stability of the silica bricks. The mechanism is that a high proportion of SiO₂ can withstand high temperatures without significant volume changes, which is essential for maintaining the structural integrity of the kiln at high temperatures.

Silica bricks with high - temperature stability can significantly reduce the deformation of the kiln body. When the kiln remains stable at high temperatures, the glass - forming process can proceed more smoothly, resulting in better - formed glass products. For example, in a glass factory, after using high - performance silica bricks, the deformation of the kiln body was reduced by a large margin, and the quality of the glass products was improved. The low - pollution characteristic of these silica bricks ensures the purity of the glass liquid. Since the silica bricks do not contaminate the glass liquid, the final glass products are of higher quality. Moreover, the low - density (lightweight) feature of silica bricks can reduce the load on the kiln structure, thereby extending the service life of the kiln. A certain glass factory reported that after using our high - performance silica bricks, the service life of the kiln was extended by 30%, and the defective product rate was reduced by 15%.

"Since we switched to these high - performance silica bricks, we've noticed a remarkable improvement in our glass quality and a significant reduction in maintenance costs. It's truly a game - changer for our production." - A satisfied glass manufacturer

Different customers have different concerns. For quality - priority customers, the high - temperature stability and low - pollution characteristics of silica bricks are the main value points. These features can ensure the high - quality production of glass products, meeting their strict quality requirements. For cost - control customers, the long - service life and low - maintenance cost of silica bricks are the key. Although the initial investment may be slightly higher, in the long run, it can save a large amount of maintenance and replacement costs. For example, choosing the right silica bricks can save millions in maintenance fees.

Let's take a look at a real - world example. A medium - sized glass factory was facing problems with high - temperature deformation of the kiln and a high defective product rate. After replacing the original refractory materials with our high - performance glass kiln silica bricks, the situation improved significantly. The high - temperature stability of the silica bricks reduced the deformation of the kiln body, which in turn improved the glass - forming quality. The low - pollution feature ensured the purity of the glass products, and the lightweight design extended the service life of the kiln. The factory not only reduced the maintenance cost but also improved the overall production efficiency.

Are you looking to enhance the performance of your glass kiln, improve glass quality, and reduce costs? Our high - performance glass kiln silica bricks are the answer. They can make your kiln more durable and your glass more pure. Click here to learn more and start building an efficient and stable glass production system today!