In high-temperature industrial applications, the reliability of refractory materials is crucial for ensuring the stability and durability of equipment. Fused magnesia bricks, as the guardians of high-temperature industries, have attracted wide attention. These bricks play an indispensable role in various high-temperature processes, from steelmaking to glass manufacturing.

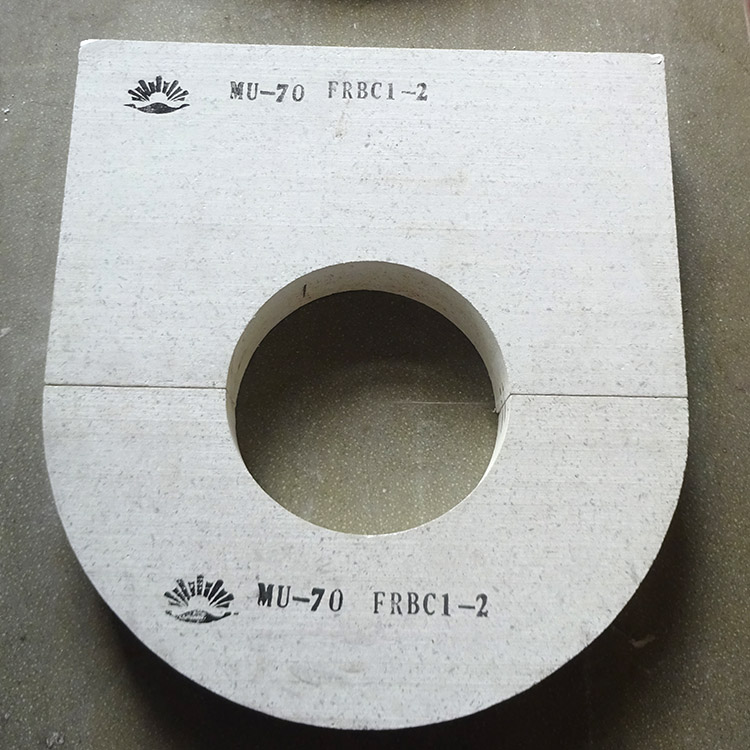

Fused magnesia bricks are primarily made from fused magnesia. The production process starts with carefully selecting high - quality fused magnesia. Then, through a reasonable particle size distribution, high - pressure molding, and high - temperature sintering, the final fused magnesia bricks are produced. This strict manufacturing process ensures the high quality and performance of the bricks.

One of the most prominent features of fused magnesia bricks is their excellent resistance to alkaline slag. In high - temperature industrial environments where alkaline slag is prevalent, such as in steel converters, these bricks can effectively resist the corrosion of alkaline slag. Tests have shown that compared with ordinary refractory bricks, the corrosion rate of fused magnesia bricks in alkaline slag environments is reduced by up to 30%, significantly extending the service life of equipment.

Fused magnesia bricks have a high refractoriness, typically above 2000°C. This means they can maintain their structural integrity and performance under extremely high - temperature conditions. In steelmaking furnaces with temperatures often exceeding 1600°C, fused magnesia bricks can ensure the normal operation of the furnace and prevent the risk of equipment failure due to high - temperature damage.

Thermal stability is another key advantage of fused magnesia bricks. They can withstand rapid temperature changes without cracking or spalling. For example, in glass melting furnaces where the temperature fluctuates during the melting and cooling processes, the good thermal stability of fused magnesia bricks ensures the long - term stability of the furnace lining.

Fused magnesia bricks are widely used in various high - temperature industrial fields:

When compared with other refractory bricks, fused magnesia bricks have obvious advantages. For example, compared with clay bricks, their refractoriness is much higher, and their resistance to alkaline slag is significantly better. In terms of thermal stability, they also outperform many other types of refractory bricks. A comprehensive comparison shows that fused magnesia bricks are a more reliable choice for high - temperature industrial applications.

According to industry reports, the demand for fused magnesia bricks in high - temperature industries has been steadily increasing in recent years. Experimental data also confirm their excellent performance. For instance, in long - term high - temperature experiments, fused magnesia bricks maintained their physical and chemical properties, further proving their reliability in high - temperature environments.

In conclusion, fused magnesia bricks are reliable refractory materials for high - temperature industrial equipment. Their excellent performance in terms of resistance to alkaline slag, high refractoriness, and good thermal stability can effectively guarantee the safety and efficiency of production. If you are looking for high - quality refractory materials for your high - temperature industrial equipment, fused magnesia bricks are definitely a top - notch choice.

Do you have any questions about fused magnesia bricks? Are you interested in learning more about their applications in your specific industry? Please feel free to leave a comment below or contact our sales team directly. We are here to provide you with detailed information and professional solutions.

Contact Us Now