In the glass manufacturing industry, the performance of glass furnaces significantly impacts production efficiency, cost, and product quality. Refractory materials, especially silica bricks, play a crucial role in the glass furnace system. This article will delve into the key role of silica bricks in glass furnaces, covering various aspects from raw material characteristics to end - user benefits.

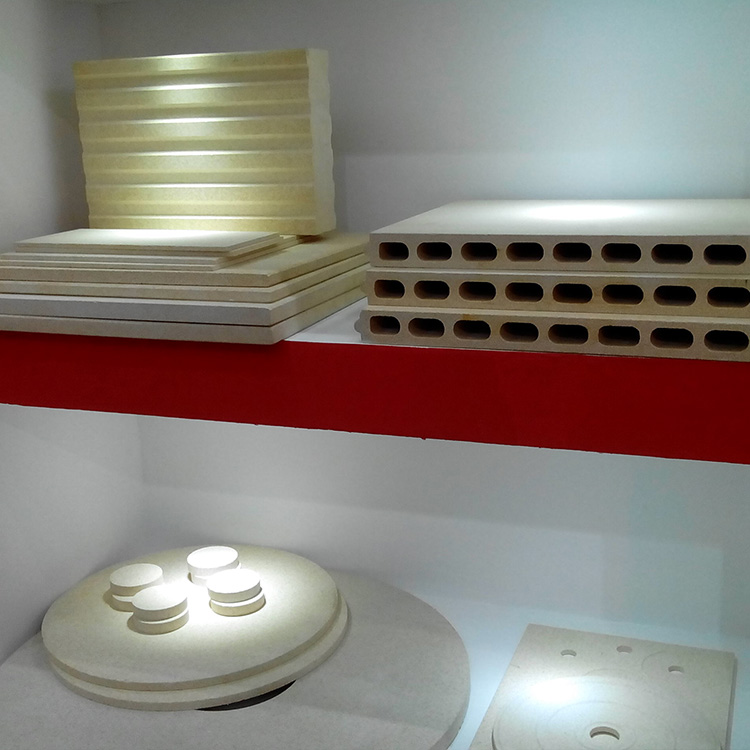

Silica bricks for glass furnaces are made from high - purity SiO₂ raw materials, with a SiO₂ content of over 96%. This high - purity raw material is the key to their excellent high - temperature resistance and volume stability. For example, compared with traditional refractory materials, the high - purity silica bricks can withstand temperatures up to 1650°C without significant deformation. The high - temperature volume stability of these silica bricks is within ±0.5% at 1550°C, ensuring the long - term stable operation of the glass furnace.

One of the most significant advantages of silica bricks is that they do not contaminate the glass melt. Traditional refractory materials may release impurities into the glass melt during high - temperature operation, affecting the quality of the glass. In contrast, high - purity silica bricks ensure the purity of the glass melt. Additionally, silica bricks have strong chemical corrosion resistance and a relatively low density. The density of silica bricks is about 1.8 - 2.0 g/cm³, which is lower than that of many traditional refractory materials, reducing the overall weight of the furnace structure. A performance comparison bar chart can clearly show these differences between silica bricks and traditional materials.

In a certain glass factory, after replacing traditional refractory materials with high - quality silica bricks in the glass furnace, the deformation rate of the furnace decreased by 30%. The high - temperature volume stability of silica bricks reduced the deformation of the furnace structure, improving the forming quality of the glass products. Moreover, the service life of the furnace was extended by more than 2 years. This case clearly demonstrates how silica bricks can reduce deformation, improve forming quality, and extend the service life of equipment.

For decision - makers and engineering technicians, quality control and cost optimization are two major concerns. In terms of quality control, silica bricks ensure the purity of the glass melt, which is crucial for high - quality glass production. In terms of cost optimization, although the initial investment in silica bricks may be slightly higher than that of traditional materials, the long - term cost savings are significant. By reducing furnace maintenance costs and extending the service life of the furnace, silica bricks can bring substantial economic benefits. The maintenance cost of a glass furnace using silica bricks can be reduced by 30% compared with that using traditional materials.

The unique technical characteristics of silica bricks, such as high - temperature resistance, volume stability, and non - contamination of the glass melt, make them an irreplaceable choice for glass furnaces. From a long - term investment perspective, choosing high - quality silica bricks means reducing the maintenance frequency of the furnace by 30% and extending the service life of the furnace by more than 2 years. This not only improves production efficiency but also brings long - term economic benefits.

In conclusion, high - quality silica bricks for glass furnaces offer significant advantages in terms of technical performance and economic benefits. If you are looking for a practical solution to optimize your glass furnace system, reduce maintenance costs, and extend equipment life, choosing our high - quality silica bricks is the right decision.