In the specialized fields of glass kilns and nuclear industries, the choice of materials plays a pivotal role in ensuring production efficiency, stability, and quality. Traditional materials often face challenges in high - temperature environments and impurity control. This article delves into the high - density zircon bricks, a revolutionary material that addresses these long - standing issues.

In professional glass kilns, especially those for alkali - free glass production, traditional materials struggle to withstand the harsh conditions. High temperatures can cause these materials to experience significant creep, reducing their structural integrity. A report from the International Glass Industry Association indicates that nearly 30% of glass production failures are related to material degradation in high - temperature environments. In the nuclear industry, controlling trace impurities is of utmost importance. Even the slightest contamination can have far - reaching consequences for nuclear processes. Traditional materials may release impurities over time, posing risks to the safety and efficiency of nuclear operations.

High - density zircon bricks exhibit excellent resistance to alkali glass corrosion. Laboratory tests have shown that they can withstand up to 50% more alkali glass erosion compared to traditional materials. This means a longer service life in glass kilns, reducing the frequency of material replacement and associated production downtime.

Under high - temperature conditions, high - density zircon bricks maintain their shape and structure. At temperatures up to 1500°C, their creep rate is less than 0.5% over a 100 - hour period, as per data from a leading materials research institute. This high - temperature stability ensures the long - term performance of glass kilns and nuclear facilities.

The high - temperature bending strength of high - density zircon bricks is another remarkable feature. They can withstand a bending stress of up to 50 MPa at 1200°C, providing reliable support in critical areas of glass kilns and nuclear reactors.

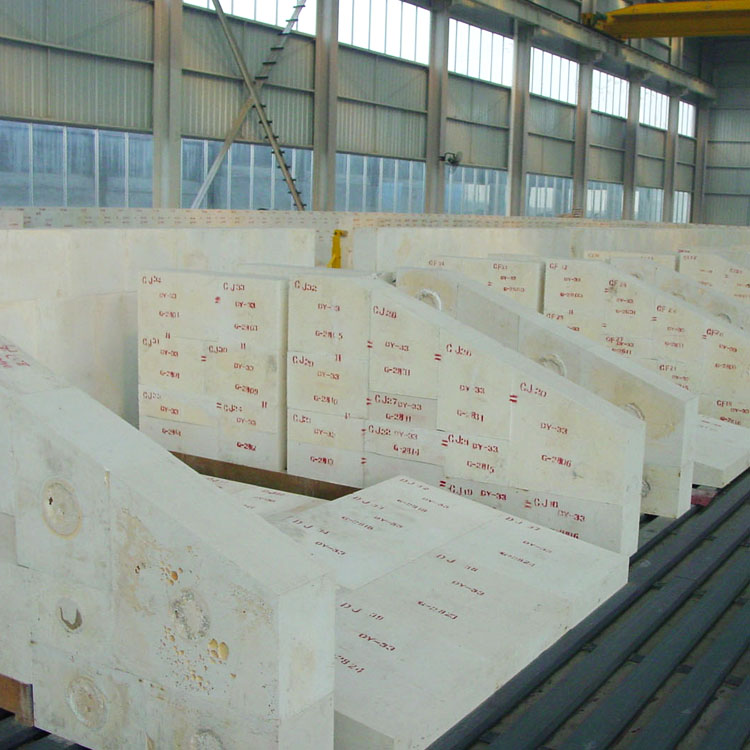

In glass kilns, high - density zircon bricks are ideal for use in the bottom of the melting pool, the forehearth, and channel blocks. These areas are subject to the most severe conditions, including high temperatures and chemical corrosion. By using high - density zircon bricks, glass manufacturers can achieve more stable production processes and higher - quality glass products. In the nuclear industry, they are used in areas where trace impurity control is crucial, effectively reducing the risk of impurity contamination.

A major glass manufacturer in Europe replaced traditional materials with high - density zircon bricks in their alkali - free glass kiln. After six months of operation, they reported a 20% increase in production efficiency and a 15% improvement in glass quality. In a nuclear power plant in Asia, the use of high - density zircon bricks in key areas led to a significant reduction in trace impurity levels, enhancing the safety and reliability of nuclear operations.

High - density zircon bricks offer a comprehensive solution to the challenges faced by the glass kiln and nuclear industries. Their outstanding performance in high - temperature resistance, alkali corrosion resistance, and impurity control makes them an indispensable material for these industries. If you are a professional glass manufacturer or a nuclear industry enterprise looking to improve production efficiency and stability, don't miss out on this opportunity. Click here to learn more about high - density zircon bricks and explore potential cooperation opportunities!