When it comes to the high - temperature parts of glass furnaces, selecting the right refractory materials is crucial for the efficiency and longevity of the operation. In this article, we'll explore the outstanding advantages of using high - purity silica sand to produce silica bricks for glass furnaces, which can help decision - makers and procurement officers in glass furnace enterprises make informed choices.

The high - temperature environment of glass furnaces poses strict requirements on refractory materials. They need to withstand extremely high temperatures, maintain stable volume at high temperatures, resist chemical corrosion, and avoid contaminating the glass melt. Traditional refractory materials often struggle to meet all these requirements simultaneously. That's where high - quality silica bricks come into play.

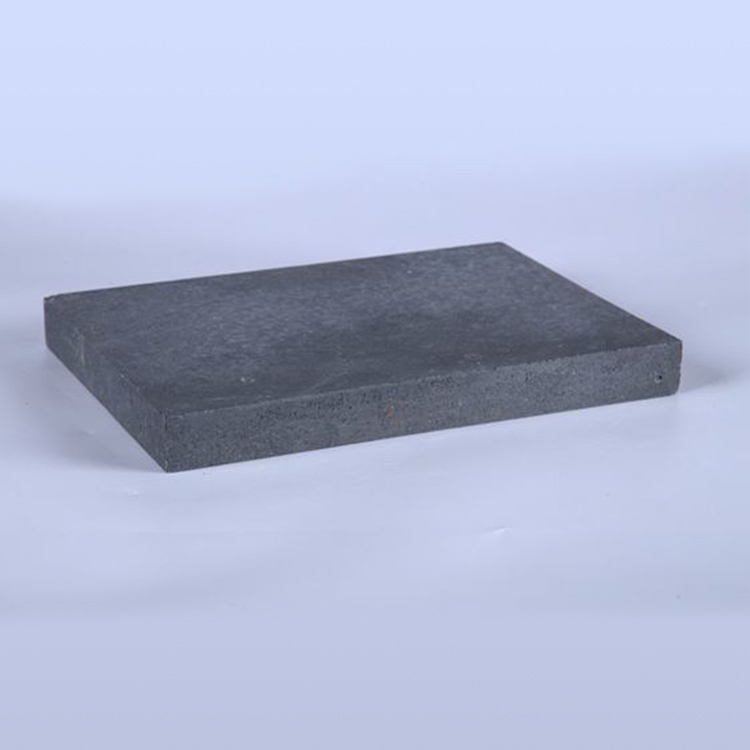

These silica bricks are made from natural high - purity silica sand with an SiO₂ content exceeding 96%. The unique composition of tridymite and cristobalite gives them excellent physical and chemical properties. For example, compared with ordinary silica sand, high - purity silica sand can form a more stable crystal structure at high temperatures, which is the key to its superior performance.

Silica bricks can withstand temperatures up to 1600°C. In a glass furnace, where the average operating temperature is around 1400 - 1500°C, these silica bricks can maintain their structural integrity. In a case study of a large - scale glass manufacturing plant, after replacing traditional refractory materials with our high - purity silica sand - made silica bricks, the furnace could operate continuously at high temperatures for an additional 3 - 5 years, greatly reducing the frequency of furnace repairs and replacements.

One of the major problems with traditional refractory materials is volume change at high temperatures, which can lead to cracks in the furnace lining. Our silica bricks have a very low coefficient of thermal expansion, less than 0.5% in the high - temperature range. This means they can maintain a stable volume during the heating and cooling cycles of the glass furnace, ensuring the long - term stability of the furnace structure.

Since the silica bricks are made from high - purity silica sand, they do not release any harmful substances into the glass melt. In a comparative test, traditional refractory materials were found to introduce impurities into the glass melt, resulting in a 5 - 10% reduction in the quality of the glass products. In contrast, our silica bricks had no such negative impact, ensuring the high - quality production of glass.

Glass furnaces are exposed to various chemical substances, such as alkalis and acids. Our silica bricks have strong resistance to chemical corrosion. In an experiment, after being immersed in a corrosive solution for 30 days, the weight loss of our silica bricks was less than 1%, while traditional refractory materials lost up to 10% of their weight, indicating their poor corrosion resistance.

The density of these silica bricks is about 1.8 - 2.0 g/cm³, which is lighter than many traditional refractory materials. This can significantly reduce the self - weight of the furnace. For a large - scale glass furnace, using our silica bricks can reduce the overall weight of the furnace by 10 - 15 tons, which not only saves construction costs but also reduces the load on the foundation of the furnace.

| Properties | High - Purity Silica Sand Silica Bricks | Traditional Refractory Materials |

|---|---|---|

| High - Temperature Resistance | Up to 1600°C | Around 1300 - 1400°C |

| Volume Stability | Low thermal expansion coefficient (<0.5%) | High thermal expansion, prone to cracking |

| Contamination of Glass Melt | None | May introduce impurities |

| Chemical Corrosion Resistance | Strong | Weak |

| Density | 1.8 - 2.0 g/cm³ | 2.2 - 2.5 g/cm³ |

Do you have any questions about the application of these silica bricks in your glass furnace? Or are you interested in knowing more about the installation and maintenance of these silica bricks? Feel free to leave your questions below.

In conclusion, high - purity silica sand - made silica bricks offer a comprehensive solution to the high - temperature refractory needs of glass furnaces. They have significant advantages in terms of high - temperature resistance, volume stability, non - contamination, chemical corrosion resistance, and light density. If you are a decision - maker or procurement officer in a glass furnace enterprise, don't miss this opportunity to improve the performance and efficiency of your glass furnace. Click here to learn more about our high - quality glass furnace silica bricks and make a smart procurement decision!