In the glass industry, the choice of refractory materials is crucial for the long - term and efficient operation of kilns. Traditional refractory materials often face problems such as short service life, poor thermal shock resistance, and easy spalling, which not only increase production costs but also affect production efficiency. Zirconia - mullite bricks have emerged as a high - performance solution to these challenges.

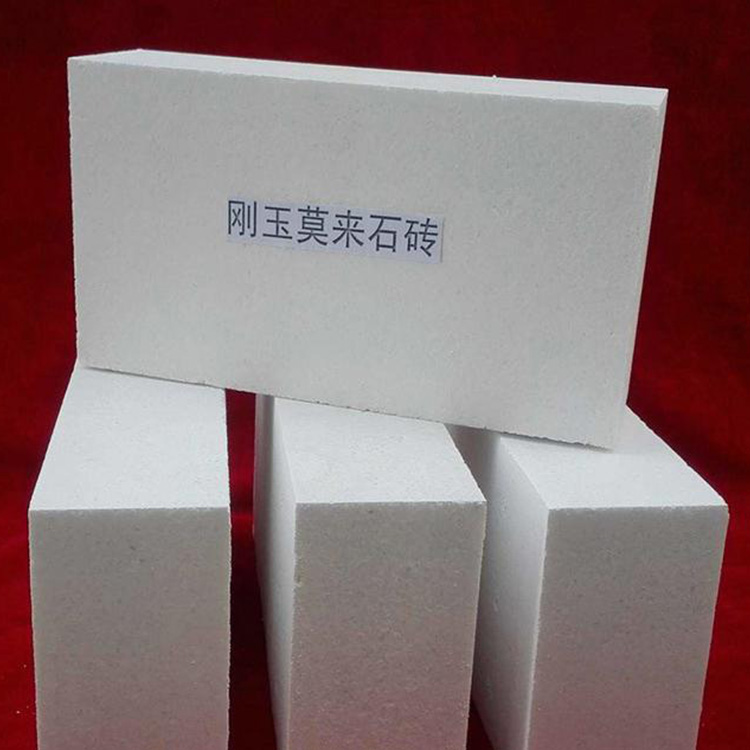

Zirconia - mullite bricks are mainly composed of fused zirconia - mullite, sintered alumina, and a binder of hydrated alumina. Fused zirconia - mullite provides high - temperature stability and excellent corrosion resistance. Sintered alumina, on the other hand, enhances the strength and density of the bricks. The hydrated alumina binder helps in the formation of a strong bond between the particles during the manufacturing process.

The composition ratios of these materials play a vital role in determining the performance of zirconia - mullite bricks. With over 70% corundum phase, more than 19% baddeleyite, and at least 7% mullite, these bricks achieve high density and purity. The high corundum content gives the bricks high hardness and strength, while the baddeleyite contributes to thermal shock resistance and corrosion resistance. The mullite phase further enhances the overall stability of the bricks.

The physical properties of zirconia - mullite bricks are directly translated into practical advantages in glass kiln applications. Their excellent thermal shock stability allows them to withstand rapid temperature changes without cracking. This means fewer production interruptions due to thermal stress. Their strong anti - spalling ability ensures that the bricks remain intact during long - term use, reducing the risk of debris falling into the molten glass.

Moreover, their high resistance to molten glass corrosion is a game - changer. In glass production, the corrosion of refractory materials by molten glass can lead to product quality issues and shortened kiln life. Zirconia - mullite bricks can effectively resist this corrosion, maintaining the integrity of the kiln lining and improving the quality of the glass products.

Let's take a look at some real - world examples. A glass manufacturing company was facing frequent kiln maintenance and short service life of their refractory materials. After switching to zirconia - mullite bricks, they witnessed a 30% increase in kiln life and a 50% reduction in production downtime. This not only saved them significant costs in terms of material replacement and maintenance but also increased their overall production efficiency.

The production of high - quality zirconia - mullite bricks requires advanced technology and strict quality control. These technical barriers ensure that only a few manufacturers can produce top - notch products. This, in turn, gives zirconia - mullite bricks a high market value. They are not just a refractory material; they are an investment in long - term and efficient glass production.

Are you also facing the problem of frequent refractory material failures? Welcome to leave a message and share your experiences. If you want to make your kiln more durable and efficient, choose zirconia - mullite bricks and embrace long - term stable operation.