In the glass industry, the choice of refractory materials is crucial for the long - term and efficient operation of kilns. Traditional refractory materials often face challenges such as low density, poor purity, and weak anti - spalling ability, which can lead to a series of problems, including reduced kiln life, low thermal shock stability, and poor resistance to molten glass erosion. However, zircon mullite bricks offer an excellent solution to these issues.

Zircon mullite bricks are mainly made from fused zircon mullite and sintered alumina. Fused zircon mullite has high purity and good crystal structure, which provides a solid foundation for the high - performance characteristics of the bricks. Sintered alumina has high hardness and excellent thermal stability. Additionally, the use of hydrated alumina binder plays a key role in enhancing the bonding strength between raw materials, ensuring the overall quality and performance of the bricks.

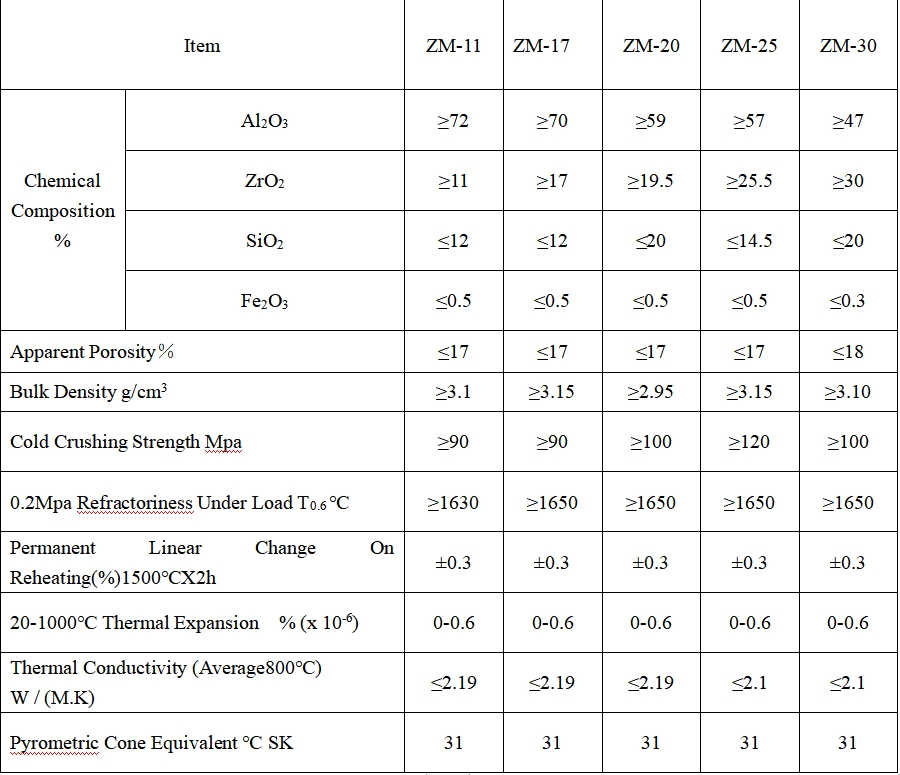

The composition of zircon mullite bricks is a carefully designed formula. It consists of more than 70% corundum phase, more than 19% baddeleyite, and more than 7% mullite. This unique composition brings high density and high purity to the bricks. The high - proportion corundum phase provides high hardness and excellent wear resistance. The baddeleyite phase enhances the thermal shock stability and anti - spalling ability of the bricks. The mullite phase improves the high - temperature strength and chemical stability of the bricks.

These physical properties of zircon mullite bricks are translated into significant practical application values. In terms of thermal shock stability, zircon mullite bricks can withstand rapid temperature changes without cracking or spalling. This is extremely important in the glass - making process, where the kiln often experiences frequent temperature fluctuations. In terms of anti - spalling ability, the bricks can maintain their integrity even under the impact of mechanical forces and thermal stress, reducing the need for frequent repairs and replacements.

When it comes to resistance to molten glass erosion, zircon mullite bricks show excellent performance. Molten glass is highly corrosive, and traditional refractory materials may be easily corroded, affecting the quality of glass production. Zircon mullite bricks, with their high - density and high - purity structure, can effectively resist the erosion of molten glass, ensuring the long - term stable operation of the glass kiln.

Let's look at some real - world customer use cases. A glass manufacturing company used traditional refractory materials in their kilns before, and the average kiln life was about 2 years. After switching to zircon mullite bricks, the kiln life was extended by more than 30%, reaching over 2.6 years. This not only reduces the frequency of kiln repairs and replacements but also significantly improves production efficiency and reduces production costs.

Another customer reported that the thermal shock stability of their kiln was greatly improved after using zircon mullite bricks. The number of kiln shutdowns caused by thermal shock problems decreased by 40%, which means more continuous and stable production.

Zircon mullite bricks have unique technical barriers that make them an irreplaceable choice in the glass industry. The precise raw material formula and strict production process ensure their high - performance characteristics. If you are still struggling with the problems of traditional refractory materials, it's time to consider zircon mullite bricks.

Let your glass kiln be more durable and your production be more efficient. Choosing zircon mullite bricks means choosing long - term stable operation. Click here to visit our official website for more information. If you have any questions, welcome to leave a message below!